Un 3481 Lithium Ion Batteries Best Practices for Safe Transport?

The transport of UN 3481 lithium ion batteries poses unique challenges. These batteries, commonly found in consumer electronics, require careful handling. Unsafe transport may lead to hazardous incidents. Understanding best practices is essential for safety.

Transporting UN 3481 lithium ion batteries involves strict guidelines. Battery size, packaging, and labeling matter greatly. Inadequate packaging may result in leaks or fires. Regular training and awareness are crucial for those involved in shipping. However, mistakes can happen. Reflection on past incidents can help improve safety measures.

The growing demand for portable power solutions increases shipping volume. This requires constant vigilance and adaptation of safety protocols. Transporters must stay updated on regulations. Balancing efficiency with safety is a complex challenge. Awareness and commitment can ensure safer movement of UN 3481 lithium ion batteries.

Best Practices for Packaging Lithium Ion Batteries for Transport

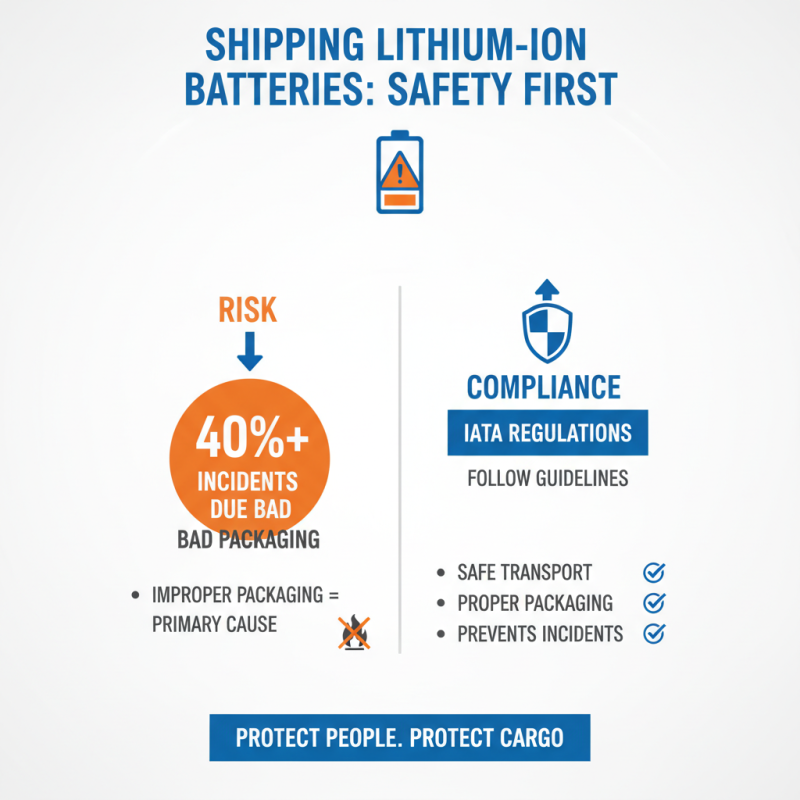

When it comes to packaging lithium-ion batteries for transport, safety is paramount. According to the International Air Transport Association (IATA), improper packaging is a leading cause of incidents during shipment. Batteries must be packed securely to prevent movement and damage. Using sturdy, non-conductive containers can mitigate risks. Each battery should be insulated to avoid contact with conductive materials.

The United Nations has established guidelines for lithium-ion battery transport. These include marking packages clearly and including relevant documentation. Reports indicate that over 1,000 incidents linked to lithium-ion batteries have occurred in the last decade. This highlights the urgent need for rigorous compliance with established protocols.

Battery capacity also plays a crucial role in shipping safety. Batteries with a capacity of over 100 watt-hours require special handling and packaging. Engaging with experienced logistics partners can enhance safety measures. However, companies must continually assess their packaging processes. Is there room for improvement? Are safety practices being updated regularly with evolving standards?

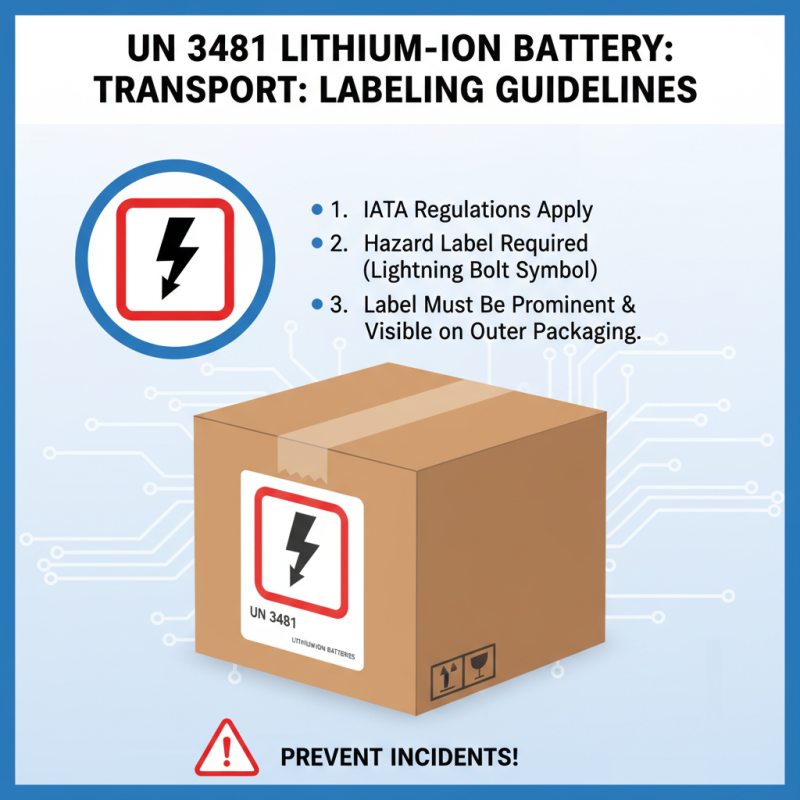

Labeling Requirements for Un 3481 Lithium Ion Batteries

When transporting UN 3481 lithium-ion batteries, proper labeling is crucial. The International Air Transport Association (IATA) sets strict guidelines. Each package must clearly display the correct hazard label. The symbol for lithium batteries is a lightning bolt within a box. This symbol must be prominent on the outer packaging. Ensuring visibility can prevent accidents during transit.

In addition to symbols, specific text is required. "Lithium-ion batteries," accompanied by a caution notice, should be included. This text alerts handlers to the potential hazards. According to the U.S. Department of Transportation (DOT), nearly 25% of battery-related incidents stem from inadequate labeling. Compliance with these standards can help reduce such risks.

Reflecting on these practices, there's always room for improvement. Some shippers overlook smaller packages, thinking they are safe. However, any battery can pose a danger if mishandled. Proper training on labeling and packaging standards is essential. This can make a difference in battery transport safety. Every detail matters in preventing disasters.

Handling Procedures for Safe Transport of Lithium Ion Batteries

Transporting lithium-ion batteries requires strict adherence to safety protocols. Improper handling can lead to fires or even explosions. According to a 2022 report by the International Fire Safety Association, more than 30% of incidents involving lithium-ion batteries occur during transportation. This statistic highlights the need for comprehensive handling procedures that minimize risks.

When packing lithium-ion batteries, always use protective materials. Each battery should be secured to prevent movement. Tape the terminals to avoid short circuits. Use non-conductive packaging that can withstand pressure during transit. Reports show that a significant 40% of battery failures stem from physical damage. This underscores the importance of robust packaging designed specifically for these batteries.

Training personnel in safe handling is crucial. Regular workshops can improve awareness of hazards. Despite best practices, errors still occur. In a recent survey, nearly 25% of workers admitted they were unsure about proper procedures. This indicates a gap that needs immediate addressing. Increased vigilance and education could significantly reduce transportation incidents.

Emergency Response Measures for Lithium Ion Battery Incidents

When dealing with lithium-ion battery incidents, effective emergency response measures are crucial. According to the National Fire Protection Association (NFPA), there were over 280 reported incidents involving battery fires in recent years. The thermal runaway of these batteries can escalate quickly. Professional training is necessary to handle such situations safely.

Proper coding and labeling of packages containing lithium-ion batteries also play a vital role. Reports indicate that 65% of transportation incidents occur due to improper packaging. First responders should always wear appropriate personal protective equipment. Immediate isolation of the hazard zone is important to protect both responders and the public.

Communication with incident command centers is essential. Information about the battery's type and hazard classification should be shared. Lack of preparedness can lead to disastrous outcomes. Inadequate training and resources can hinder response efforts. Situational awareness is critical for safety. The industry needs to reflect on current practices and strive for improvement.

Regulatory Compliance for Shipping Lithium Ion Batteries Safely

Shipping lithium-ion batteries requires careful adherence to regulatory standards to ensure safety. According to the International Air Transport Association (IATA), improper packaging is a primary cause of incidents during transport. In fact, over 40% of lithium battery incidents occur due to inadequate packing. This emphasizes the importance of following guidelines.

When shipping these batteries, it's crucial to use UN-approved packaging that can withstand rough handling. The packaging should be labeled clearly, indicating the battery type and any hazards. Batteries must be securely arranged to avoid movement and short-circuiting. Don't overlook small details; even a minor oversight can lead to severe consequences.

**Tips:** Always inspect your packaging materials before each shipment. Use protective padding for extra safety. Consider potential environmental factors during transport, such as temperature extremes.

Understanding these regulations is essential. The US Department of Transportation states that shipping lithium-ion batteries requires specific documentation. Many companies fail to keep up with the latest changes in regulations. This negligence can lead to fines and increased scrutiny. Make it a point to stay informed about industry updates and training opportunities.