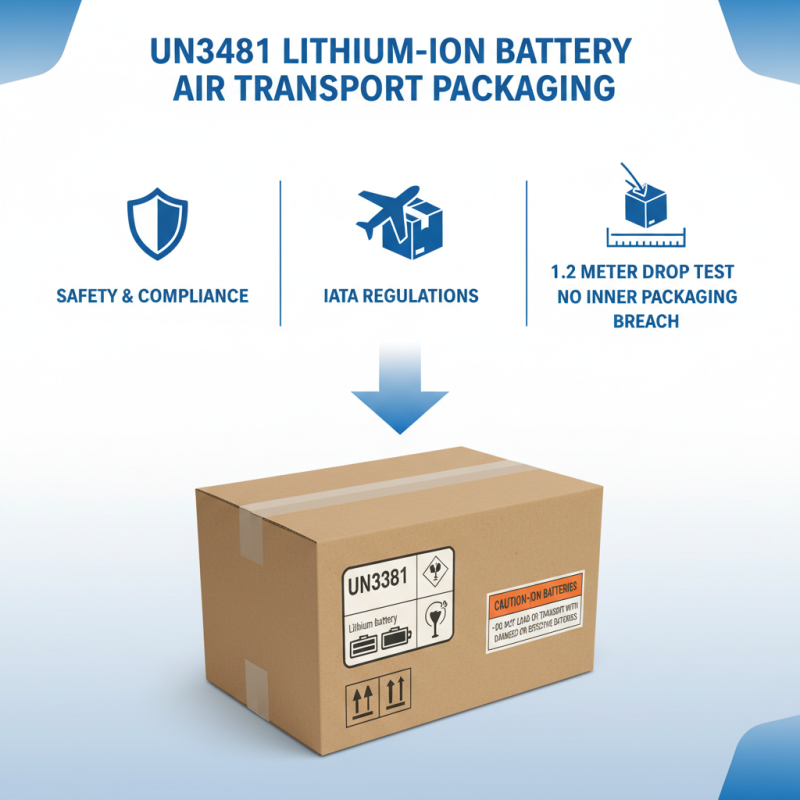

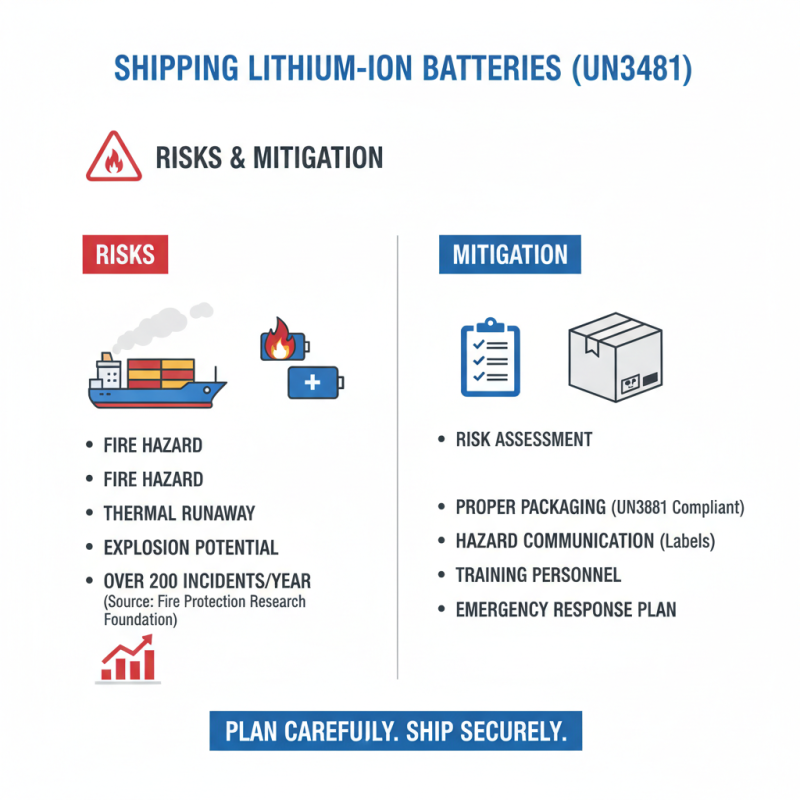

| Proper Packaging |

Use UN approved packaging with appropriate labeling. |

Isolate the incident area and move away from ignition sources. |

Local emergency services: 911 |

| Battery State of Charge |

Ship batteries at a charge level between 30% and 50%. |

Evacuate personnel and call for hazardous material teams. |

Hazardous Materials Team: 1-800-555-0199 |

| Transport Regulations |

Follow all national and international transport regulations. |

Inform authorities and provide documentation to first responders. |

National Transport Agency: 1-800-555-0210 |

| Training Personnel |

Ensure all personnel are trained in handling and shipping lithium batteries. |

Conduct a safety briefing immediately in case of an incident. |

Training Coordinator: 1-800-555-0176 |

| Labeling and Marking |

Clearly label packages as containing lithium batteries. |

Prepare to contain leaks or spills and notify emergency teams. |

Emergency Spill Response: 1-800-555-0188 |