2026 How to Choose Stainless Steel Woven Wire Mesh Safely?

Choosing the right stainless steel woven wire mesh is crucial for many industries. An expert in the field, Dr. Emily Carter, states, "Selecting the proper mesh can make or break your project's success." Her insight emphasizes the importance of informed choices.

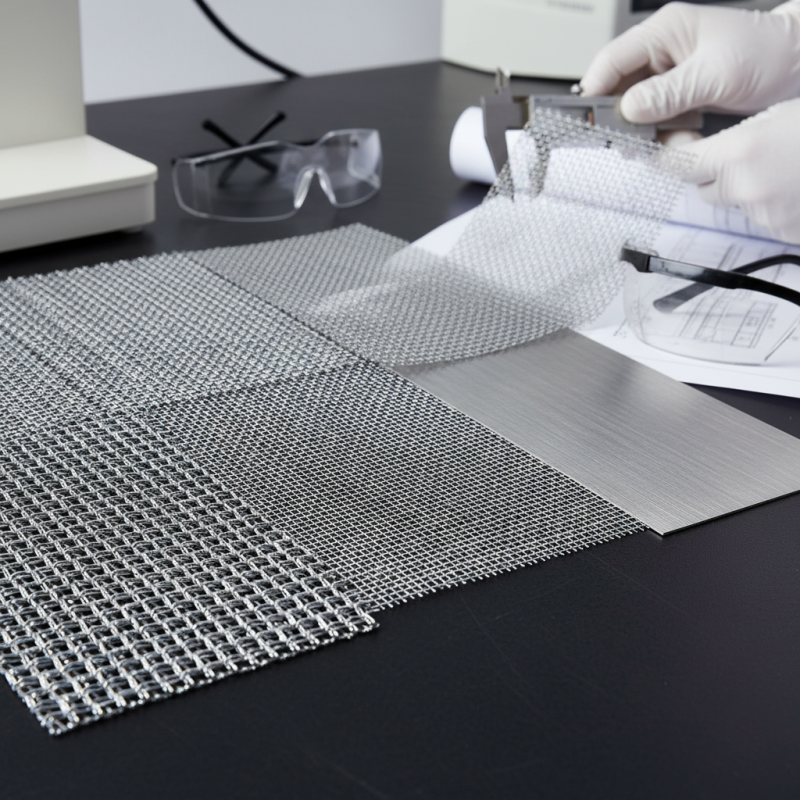

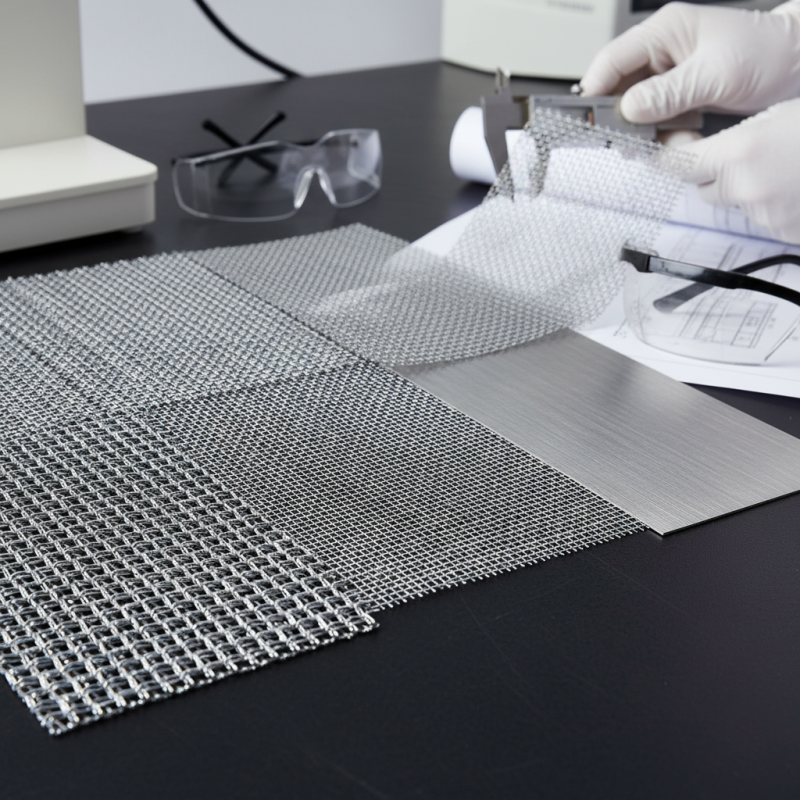

stainless steel woven wire mesh is used in filtration, reinforcement, and safety applications. It offers strength and durability. However, not all products are the same. Different grades and specifications exist. This can lead to confusion for buyers. Understanding the specific needs of your project is vital.

Each application requires careful consideration of mesh size, wire thickness, and material grade. For instance, an architectural application may prioritize aesthetics, while a filtration project demands high precision. Without proper knowledge, buyers may end up with unsuitable products. Errors can lead to costly consequences. Evaluating your requirements is essential for a successful purchase.

Understanding the Different Types of Stainless Steel Woven Wire Mesh

When selecting stainless steel woven wire mesh, understanding its types is crucial. There are various types available, each with unique properties. Some common types include plain weave, Dutch weave, and twill weave. These variations affect the mesh’s strength, flexibility, and application.

Plain weave is the most basic type. It offers good stability and is often used in sieving and filtration. Dutch weave provides tighter openings, making it suitable for finer filtration applications. Twill weave offers better strength and resistance to wear, making it ideal for heavy-duty tasks.

Tips: Always check the wire diameter. Thicker wires can enhance durability but may alter flexibility. Consider the mesh opening size as well. Smaller openings will filter finer particles but can restrict fluid flow.

Before making your decision, think about your specific needs. Will the mesh face harsh conditions? Reflect on whether maintenance requirements fit your capabilities. Each type of woven wire mesh serves a purpose, but choosing the right one means understanding your unique application.

Key Factors to Consider When Choosing Wire Mesh for Safety

When selecting stainless steel woven wire mesh, safety is paramount. Key factors must be carefully considered to ensure reliable performance. The mesh's weave pattern impacts its strength and flexibility, affecting its ability to withstand physical stresses. A report by the Metal Construction Association notes that correct mesh specifications can enhance durability by up to 20%.

Material grade matters too. High-quality stainless steel is essential for corrosion resistance. According to industry standards, 304 and 316 grades are popular choices due to their superior longevity. Always check the mesh's load-bearing capacity. This ensures it meets safety requirements for your specific application.

**Tips:** Always inquire about the source of the stainless steel. Transparency can indicate quality. Test samples when possible. Sometimes, the best products aren’t what they seem. Safety should not be compromised for cost. Consider long-term needs over immediate savings.

Assessing the Mesh Size and Wire Diameter for Your Needs

When selecting stainless steel woven wire mesh, assessing the mesh size and wire diameter is crucial. The mesh size determines how tightly the wires are woven together. A smaller mesh size means finer openings. This may be ideal for filtering liquids or small particles. Larger mesh sizes, on the other hand, allow for better airflow and visibility, which can benefit various applications, like enclosures or safety barriers.

Wire diameter is equally important. A thicker wire provides greater strength and durability. However, it can also limit flexibility. For lightweight applications, a thinner wire might work well. Yet, this choice can compromise the mesh’s structural integrity over time. Balancing these two factors requires careful consideration. Reflecting on the specific needs of your project will help. Each option carries its pros and cons, requiring a thoughtful evaluation of trade-offs.

2026 How to Choose Stainless Steel Woven Wire Mesh Safely?

This chart illustrates recommended values for selecting stainless steel woven wire mesh, focusing on mesh size measured in microns and wire diameter in millimeters. These factors are crucial in determining the safety and functionality of the mesh in various applications.

Evaluating the Corrosion Resistance and Durability of Stainless Steel

When choosing stainless steel woven wire mesh, corrosion resistance and durability are critical factors. According to a report by the International Stainless Steel Forum, stainless steel can resist corrosion in various environments. The specific alloy composition significantly impacts its longevity. For instance, 304 stainless steel offers decent corrosion resistance, while 316 provides enhanced protection against chlorides.

Environmental conditions also play a vital role. In coastal areas, for instance, even 316 stainless steel can face corrosion from saltwater exposure. This highlights that even high-grade materials have limitations. Regular maintenance might be needed to ensure longevity. A study indicated that applying protective coatings can enhance the durability of stainless steel mesh in harsh environments.

Monitoring the conditions where the mesh will be used is essential. The mesh may degrade faster in polluted areas due to aggressive elements in the atmosphere. Therefore, it's crucial to assess each specific situation. Understanding that no material is completely corrosion-proof helps inform safer choices in material selection.

Best Practices for Installation and Maintenance of Wire Mesh Safety

When installing stainless steel woven wire mesh, proper practices ensure safety and durability. Industry reports indicate that about 35% of mesh-related accidents stem from improper installation. Therefore, precise measurements are crucial. Always double-check dimensions before cuts. Use certified tools for accurate installation.

Tips: Ensure the mesh size suits your project needs. This impacts strength and integrity. Smaller mesh openings provide better protection but may reduce visibility.

Regular maintenance is just as important. Clean the mesh periodically to prevent corrosion. Use a mild soap solution and a soft brush. Avoid harsh chemicals that might damage the wire. Inspections should occur at least bi-annually. Look for signs of wear or damage.

Tips: Document all maintenance activities. This creates a reliable history. Unknown conditions can lead to unexpected failures. Always involve a professional when in doubt. It can save time and resources.