A Comprehensive Comparison of Industrial Lithium Batteries Performance and Efficiency

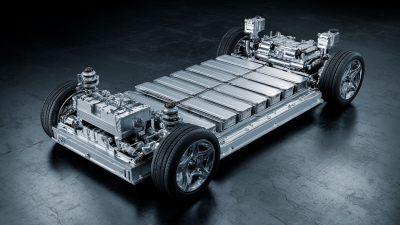

In today's rapidly evolving industrial landscape, the demand for efficient and reliable energy storage solutions has never been greater. Industrial lithium batteries have emerged as a crucial technology, powering everything from heavy machinery to renewable energy systems. This comprehensive comparison of industrial lithium batteries' performance and efficiency aims to delve into the various options available in the market, exploring their capabilities, advantages, and limitations. By analyzing key performance metrics such as energy density, charging time, cycle life, and environmental impact, we aim to equip industry professionals with the insights necessary to make informed decisions. As industries continue to seek sustainability and efficiency, understanding how different industrial lithium batteries stack up against each other will be vital in navigating the future of energy storage solutions.

Key Performance Metrics of Industrial Lithium Batteries: A Data-Driven Analysis

When it comes to evaluating the performance and efficiency of industrial lithium batteries, there are several key performance metrics that industry professionals must consider. Data from a recent report by the International Energy Agency (IEA) indicates that lithium batteries can achieve energy densities of up to 250 Wh/kg, making them ideal for applications requiring long discharge times and high energy output. Additionally, the cycle life of these batteries can reach up to 5000 cycles, significantly reducing operational costs over their lifespan.

One critical metric is the battery's charge-discharge efficiency, which can exceed 90% for high-quality lithium batteries, minimizing energy losses during operation. Furthermore, advancements in thermal management systems have greatly enhanced the temperature stability of these batteries, allowing them to operate effectively in a wider range of environments. According to the Battery University, optimal thermal management can improve the overall performance by up to 20%.

Tips: When selecting industrial lithium batteries, look for models with high cycle life and efficiency ratings. Regular maintenance and monitoring of battery temperature can further enhance longevity and performance. Lastly, consider incorporating batteries that offer comprehensive data analytics, providing insights on usage, lifecycle, and efficiency which can drive informed decision-making in industrial applications.

Comparative Study of Charge and Discharge Efficiency Across Different Lithium Battery Types

In the rapidly evolving landscape of industrial lithium batteries, the charge and discharge efficiency emerges as a critical parameter in assessing their performance. A comprehensive study revealed that lithium iron phosphate (LiFePO4) batteries provide an exceptional cycle life with a charge efficiency of approximately 95% and discharge efficiency nearing 90%. This makes them preferable for applications requiring long-term reliability, such as electric vehicles and renewable energy storage systems. In contrast, lithium nickel manganese cobalt oxide (NMC) batteries, commonly used in high-performance applications, exhibit slightly lower efficiency rates. Reports indicate their charge efficiency at around 90% and discharge efficiency of about 85%, highlighting a trade-off between efficiency and energy density.

Further analysis shows that newer advancements in lithium-sulfur and solid-state batteries are pushing the boundaries of efficiency. For instance, lithium-sulfur batteries have demonstrated a charge efficiency as high as 96% in laboratory settings, paired with a considerable energy density increase, indicating a promising future for innovation in this sphere. Solid-state batteries, although still in the developmental phase, have shown potential charge efficiencies exceeding 90% with safer operation and reduced degradation over time. As industry demands evolve, focusing on charge and discharge efficiency will be paramount in selecting the appropriate battery technology for various industrial applications.

Lifetime and Reliability: An In-Depth Look at Industry-Standard Testing and Results

When evaluating industrial lithium batteries, lifetime and reliability are critical factors that determine their performance in demanding environments. Industry-standard testing methods, such as accelerated aging tests and cycle life assessments, provide valuable insights into how these batteries endure over time. These tests simulate real-world usage scenarios, allowing manufacturers to gauge the batteries' capacity retention under various conditions, including temperature fluctuations and load variations.

Moreover, the results from these thorough evaluations help establish benchmarks for reliability. A battery's ability to maintain efficiency over extended periods not only influences operational costs but also the overall trust in the technology. By analyzing failure rates and the factors leading to degradation, stakeholders can make informed decisions when selecting batteries for crucial applications. Consequently, understanding lifetime and reliability through comprehensive testing empowers industries to invest in the most efficient lithium battery solutions tailored for their specific needs.

Cost vs. Efficiency: Evaluating the Economic Factors in Lithium Battery Selection

When selecting industrial lithium batteries, the balance between cost and efficiency plays a critical role in the decision-making process. While higher efficiency often translates to longer operational life and reduced energy consumption, the initial investment for such batteries can be significantly higher. Companies must perform a thorough analysis to determine which battery type offers the best performance for their specific applications while remaining economically viable. Factors such as maintenance costs, energy savings, and potential downtime can affect the long-term return on investment.

Another key aspect to consider is the rapid evolution of lithium battery technology. As new materials and designs emerge, the cost of high-efficiency batteries may decrease, making them more accessible for various industries. Additionally, government incentives and technological advancements can further influence economic factors in battery selection. Therefore, it’s essential for stakeholders to stay informed about industry trends and technological breakthroughs that could impact their choices, ensuring they invest in the most cost-effective and efficient solutions available for their operational needs.

Environmental Impact Assessment: Addressing Sustainability in Industrial Lithium Battery Use

The growing reliance on industrial lithium batteries has sparked a crucial conversation around their environmental impact. As these batteries dominate the energy landscape due to their efficiency and high performance, it is equally important to evaluate their sustainability. The extraction of lithium, often associated with significant ecological disruption, raises red flags concerning water usage, habitat destruction, and carbon footprint. Therefore, understanding the full cycle of lithium production—from mining to disposal—becomes essential in assessing their long-term sustainability.

Moreover, advancements in recycling technologies offer a glimmer of hope for mitigating the environmental consequences of industrial lithium batteries. By rethinking battery lifecycle management, industry stakeholders can harness recycled materials to significantly reduce waste and lower the demand for raw lithium extraction. This not only conserves natural resources but also minimizes the overall carbon emissions associated with battery production. As industries adopt more sustainable practices, the environmental impact of lithium batteries can be addressed more effectively, paving the way for an eco-friendlier energy future.

A Comprehensive Comparison of Industrial Lithium Batteries Performance and Efficiency - Environmental Impact Assessment: Addressing Sustainability in Industrial Lithium Battery Use

| Battery Type |

Energy Density (Wh/kg) |

Cycle Life (Charge/Discharge) |

Charge Time (Hours) |

Environmental Impact (CO2 Emissions per kWh) |

| Lithium Iron Phosphate (LiFePO4) |

90-160 |

2000-3000 |

4-5 |

120-150 |

| Lithium Nickel Manganese Cobalt (NMC) |

150-250 |

1000-1500 |

1-2 |

150-200 |

| Lithium Cobalt Oxide (LCO) |

150-200 |

500-1000 |

2-3 |

200-250 |

| Lithium Manganese Oxide (LMO) |

100-150 |

1000-2000 |

1-2.5 |

130-180 |