7 Essential Insights for Shipping Label Lithium Battery Success

In the rapidly evolving landscape of e-commerce and logistics, the transportation of lithium batteries presents unique challenges and complexities. Understanding the nuances of shipping label lithium battery practices is crucial for businesses looking to ensure compliance and safety in their shipping operations. This blog will explore seven essential insights that can help streamline the shipping process, mitigate risks, and enhance efficiency when dealing with lithium batteries. From regulatory requirements to best practices in labeling and packaging, we will provide a comprehensive comparison of successful strategies that organizations can adopt. By equipping yourself with this knowledge, you can navigate the intricate world of lithium battery shipping with confidence and foster greater success in your logistics endeavors.

Understanding Lithium Battery Regulations for Shipping

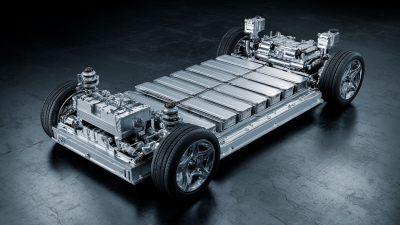

Shipping lithium batteries presents unique challenges due to stringent regulations aimed at ensuring safety. Understanding these regulations is crucial for anyone involved in the shipping process. The International Air Transport Association (IATA) and the United Nations (UN) have established guidelines to mitigate the risks associated with transporting lithium batteries, including their potential to ignite or explode under certain conditions. Familiarizing yourself with the specific classifications, packaging requirements, and labeling standards is paramount for compliance.

Proper classification of lithium batteries is essential; they are categorized into two main types: lithium-ion and lithium metal batteries, each with distinct regulations. Packaging plays a critical role, requiring specific materials and containment strategies to prevent short-circuiting and damage during transit. Additionally, accurate labeling, including the UN number and hazard labels, helps inform handlers of the potential risks. By thoroughly understanding and adhering to these regulations, businesses can ensure safe shipping practices while minimizing delays and potential fines, fostering a smoother logistics process in the competitive battery market.

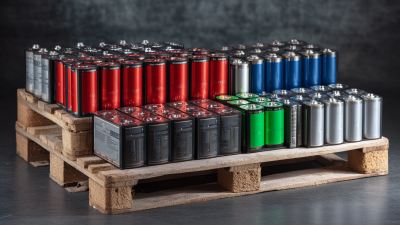

Choosing the Right Packaging for Lithium Batteries

When it comes to shipping lithium batteries, choosing the right packaging is essential for regulatory compliance and safety. According to the IATA, improper packaging is a leading cause of incidents involving lithium batteries during transport. Specific guidelines, such as UN3480 for standalone lithium-ion batteries, stipulate requirements for packaging that can withstand the rigors of transit while preventing short circuits and thermal runaway.

Data from the U.S. Department of Transportation indicates that nearly 80% of all lithium battery shipments are transported by air, underscoring the importance of using materials that meet stringent aviation safety standards. This means that your packaging must not only protect the batteries but also comply with labeling requirements and hazard warnings. As per a recent report by the Battery Safety Council, better packaging solutions lead to a 30% reduction in incidents related to shipping failures. Utilizing approved packaging materials such as UN-certified boxes and cushioning can vastly improve the safety profile of lithium battery shipments.

Labeling Essentials: What You Need for Compliance

When it comes to shipping lithium batteries, accurate labeling is paramount for compliance with international regulations. According to the International Air Transport Association (IATA), improper labeling can lead to serious safety hazards, evidenced by over 200 incidents in the past five years involving lithium battery fires during transport. This underscores the importance of adhering to the stringent labeling requirements set by organizations like the UN and IATA. Proper labeling not only facilitates safer transport but also ensures that packages are handled correctly throughout the shipping process.

In addition, compliance with the latest regulations can significantly impact your business operations. A report from the Federal Aviation Administration (FAA) indicates that businesses face fines of up to $175,000 per violation for non-compliance with hazardous materials regulations. This hefty price tag serves as a stark reminder that investing in proper labeling practices is both a legal requirement and a cost-saving measure. By understanding the essential labeling elements, such as using the correct hazard symbols and providing clear handling instructions, businesses can mitigate risks and enhance their shipping efficiency while maintaining compliance.

7 Essential Insights for Shipping Label Lithium Battery Success - Labeling Essentials: What You Need for Compliance

| Insight |

Description |

Best Practice |

| Label Clarity |

Ensure that all labeling is legible and clear to avoid misunderstandings. |

Use large, bold fonts and high-contrast colors. |

| Regulatory Compliance |

Comply with all local and international shipping regulations regarding lithium batteries. |

Regularly review regulations and update labels accordingly. |

| Hazard Symbol |

Include appropriate hazard symbols as indicated by regulations. |

Use standardized symbols to improve recognition. |

| Weight Limitations |

Adhere to weight limitations for lithium battery shipments to prevent disruptions. |

Check carrier guidelines for weight restrictions. |

| Proper Packaging |

Use approved packaging materials to secure lithium batteries during transport. |

Follow ISPM 15 guidelines to ensure packaging compliance. |

| Handling Instructions |

Provide clear handling instructions to prevent accidents. |

Include instructions on the label for emergency procedures. |

| Training Staff |

Train staff on proper labeling and shipping procedures for lithium batteries. |

Conduct regular training sessions to keep staff informed about updates. |

Best Practices for Shipping Lithium Batteries Internationally

When shipping lithium batteries internationally, understanding the regulatory landscape is essential. Different countries have varying rules regarding the transportation of lithium batteries, especially considering their flammable nature. Always start by familiarizing yourself with the specific requirements of your destination country, as elements such as battery capacity, shipping method, and packaging can greatly influence compliance. Utilizing resources from regulatory bodies and freight forwarders who specialize in hazardous materials can provide clarity on these critical regulations.

Additionally, proper packaging is crucial for ensuring safe transport. Lithium batteries should be packed in sturdy, non-conductive materials to prevent short-circuiting. It is also advisable to use cushioning materials to protect the batteries from physical impact during transit. Ensure that each package is labeled correctly, and include necessary documentation to facilitate smooth customs clearance. By adopting these best practices, shippers can significantly reduce the risk of delays, fines, and accidents, while ensuring that their lithium battery shipments reach their destinations safely and efficiently.

7 Essential Insights for Shipping Lithium Batteries Internationally

Common Missteps in Lithium Battery Shipping to Avoid

When shipping lithium batteries, adhering to safety regulations is paramount. One common misstep is failing to properly classify the batteries. Many shippers mistakenly assume that all lithium batteries fall into the same category, overlooking the fact that there are specific guidelines depending on whether they are lithium-ion or lithium metal. Neglecting to distinguish between these types can lead to significant penalties, product recalls, or even dangerous situations during transportation.

Another frequent mistake is inadequate labeling and documentation. Shippers often underestimate the importance of clear, compliant labels. It’s essential to include relevant hazard symbols and ensure that the accompanying documentation explicitly states the battery type and its specifications. Failing to do so can result in delays, additional costs, and potentially hazardous situations if the packages are mishandled. Additionally, ensuring that the packaging meets regulatory standards is crucial—using subpar materials could lead to leaks or breaches, jeopardizing both safety and compliance.