What You Need to Know About Lithium Auto Battery Technologies

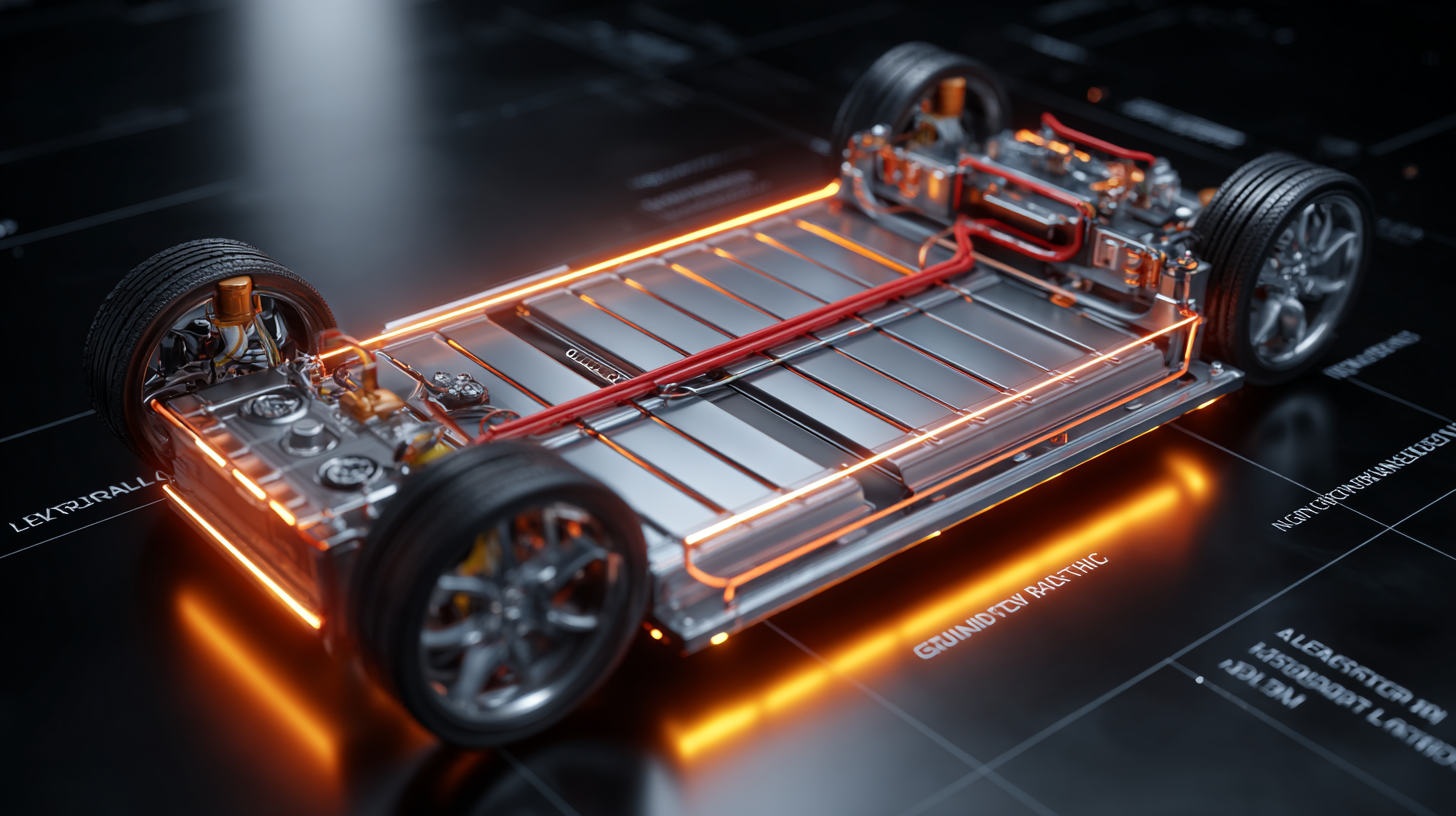

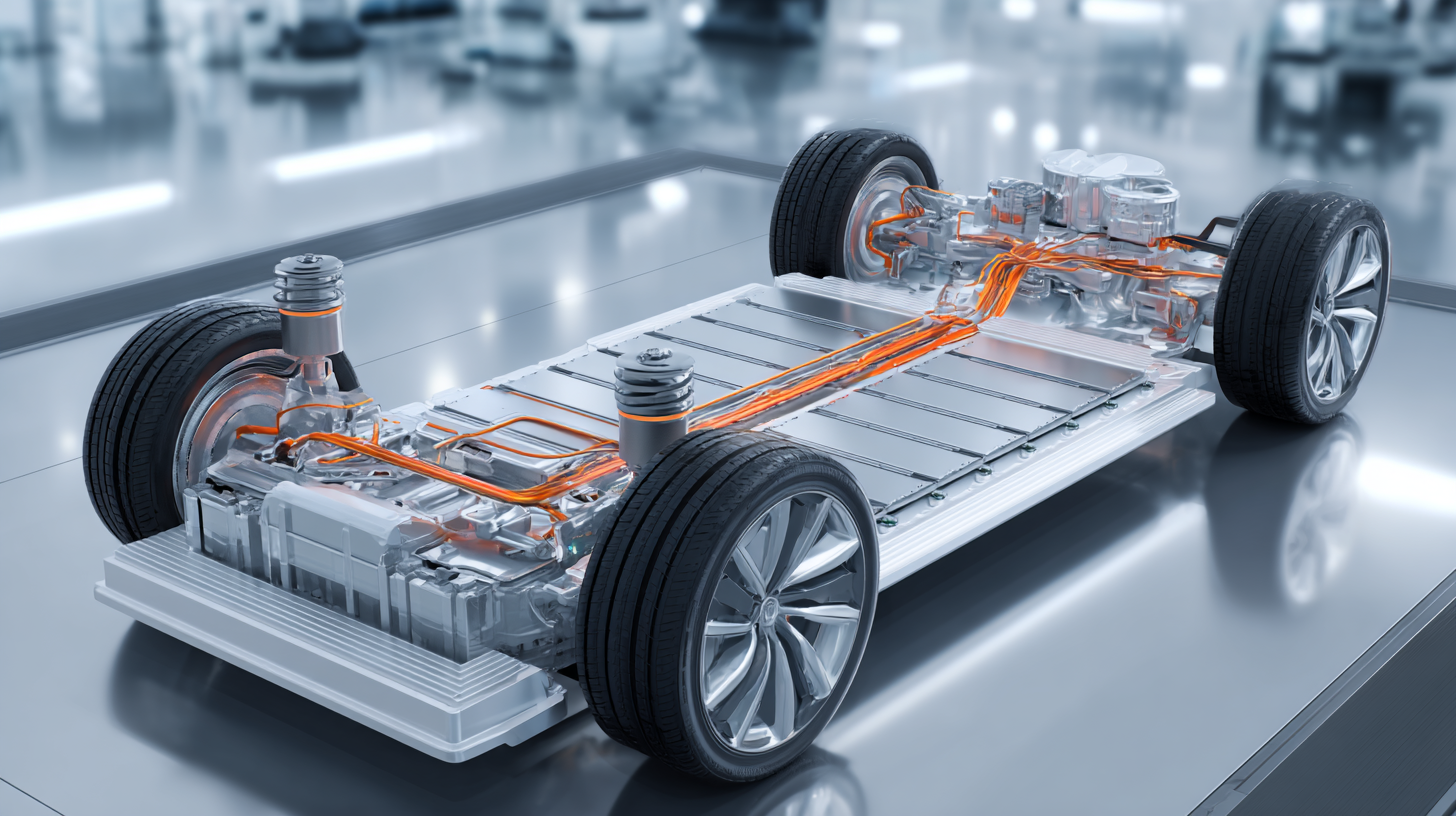

As the automotive industry shifts towards sustainable energy solutions, lithium auto battery technologies have emerged as a cornerstone of this transformation. According to a report by the International Energy Agency (IEA), the global demand for lithium-ion batteries is projected to increase by more than 30 times by 2030, driven predominantly by the electric vehicle (EV) market, which is expected to reach over 30% of total car sales within the same timeframe.

Lithium auto batteries offer a unique combination of energy density, longevity, and efficiency, making them the preferred choice for manufacturers and consumers alike. However, understanding the intricacies of these technologies, including the various types of lithium batteries available and their respective advantages and limitations, is crucial for stakeholders aiming to navigate the rapidly evolving landscape of electric mobility.

Understanding Lithium-Ion vs. Lithium Polymer: Key Differences Explained

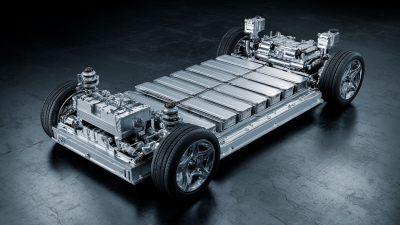

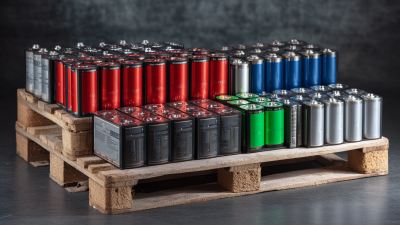

Lithium-ion (Li-ion) and lithium polymer (LiPo) batteries are two predominant technologies powering electric vehicles (EVs) today, each with distinct characteristics tailored for different applications. According to a report by the International Energy Agency (IEA), the global demand for EVs is projected to reach over 30 million units annually by 2030, highlighting the critical role of battery technology innovation. Li-ion batteries are favored for their high energy density, making them suitable for longer-range applications, achieving energy densities between 150-250 Wh/kg. This capability allows automakers to design vehicles that deliver extended driving ranges.

On the other hand, lithium polymer batteries are known for their lightweight and flexible form factor, allowing for diverse designs and configurations. They typically offer comparable energy densities to Li-ion batteries but with a slightly lower performance in some instances, around 100-180 Wh/kg. However, their ability to be manufactured in thin profiles makes them ideal for compact spaces within modern EV designs. As the competition between these technologies continues, according to a BloombergNEF report, the cost of Li-ion batteries has dropped by 89% since 2010, significantly influencing EV affordability and accessibility, while advancements in LiPo technologies are also gaining traction as manufacturers seek varied performance parameters.

Comparative Analysis of Lithium-Ion vs. Lithium Polymer Battery Technologies

This chart compares key performance metrics of Lithium-Ion and Lithium Polymer battery technologies, highlighting their strengths and weaknesses across various dimensions.

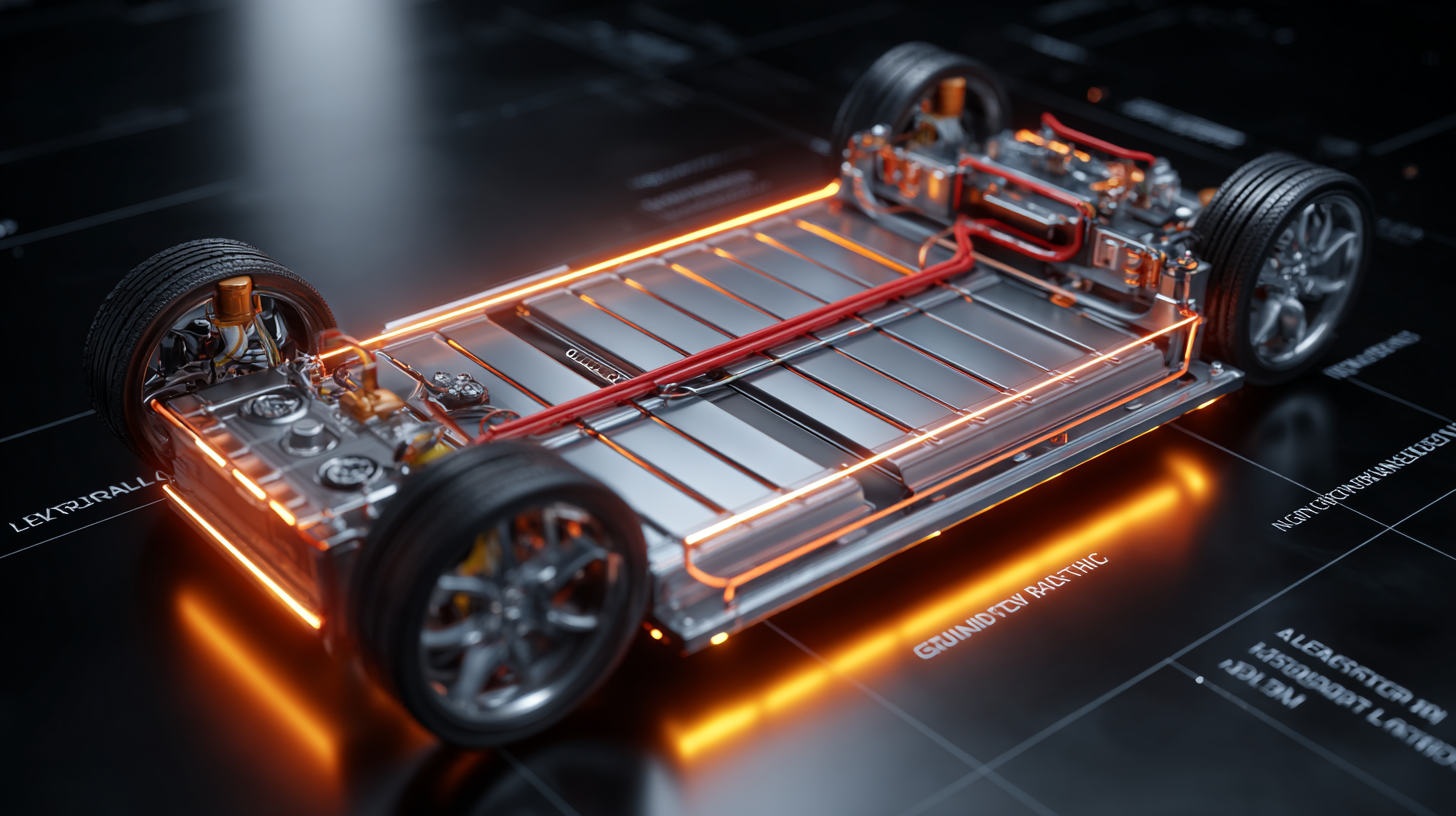

Advantages of Lithium Auto Batteries: Why They're Taking Over the Market

Lithium auto batteries are rapidly becoming the preferred choice in the automotive industry, significantly outpacing traditional lead-acid and nickel-based options. One of the primary advantages of lithium batteries is their high energy density, which allows for lighter, more compact designs while still delivering ample power. This not only enhances vehicle performance but also increases the overall driving range, addressing one of the critical concerns for electric vehicle (EV) owners. As automakers continuously strive to improve efficiency, lithium batteries become an essential component in achieving these goals.

Lithium auto batteries are rapidly becoming the preferred choice in the automotive industry, significantly outpacing traditional lead-acid and nickel-based options. One of the primary advantages of lithium batteries is their high energy density, which allows for lighter, more compact designs while still delivering ample power. This not only enhances vehicle performance but also increases the overall driving range, addressing one of the critical concerns for electric vehicle (EV) owners. As automakers continuously strive to improve efficiency, lithium batteries become an essential component in achieving these goals.

Another key benefit of lithium batteries is their impressive cycle life. Unlike their counterparts that may suffer from rapid degradation, lithium batteries can endure hundreds of charging cycles with minimal loss in capacity. This longevity translates to lower replacement costs for consumers and reduced environmental impact, as fewer batteries are discarded over time. Furthermore, advancements in lithium technology, such as improved thermal management and faster charging capabilities, are making these batteries even more attractive, prompting a surge in their adoption across the market. With such compelling advantages, it's clear why lithium auto batteries are taking over the automotive landscape.

The Future of Lithium Battery Technology: Trends and Innovations to Watch

The future of lithium battery technology is poised for transformative advancements, driven by the growing need for energy-efficient solutions in the booming electric vehicle (EV) market. Innovations such as solid-state batteries are emerging, which promise to enhance safety and performance by replacing the liquid electrolytes found in conventional lithium-ion cells with solid materials. This shift not only increases energy density but also extends battery life, addressing two critical issues that have long plagued electric vehicles.

Another trend to watch is the integration of artificial intelligence in battery management systems. AI can optimize charging cycles and predict battery degradation, allowing for smarter energy usage and longer lifespans. With breakthroughs in recycling technologies also on the horizon, the industry is moving towards a circular economy approach, where lithium from old batteries can be effectively recovered and repurposed, thereby minimizing environmental impact. These trends indicate a future where lithium battery technology not only drives transportation forward but does so sustainably, making electric mobility more accessible and environmentally friendly.

Challenges Facing Lithium Battery Production and Sustainability Efforts

The production of lithium batteries for electric vehicles (EVs) faces significant challenges that impact sustainability efforts in the industry. One of the primary concerns is the environmental cost of lithium extraction. The mining process often depletes water resources in arid regions and can lead to habitat destruction. Additionally, the reliance on mining practices raises questions about the long-term viability of these resources, as well as the social implications for communities near extraction sites.

Another challenge is the lifecycle management of lithium batteries. As the demand for electric vehicles rises, the volume of spent batteries needing proper disposal or recycling is expected to increase dramatically. Current recycling processes are limited and often inefficient, leading to a considerable amount of waste. Advancements in recycling technology and increased commitment from manufacturers are essential to ensure that materials from old batteries can be recovered and reused, significantly reducing the demand for new lithium extraction and the associated environmental impacts.

Safety Measures and Best Practices for Lithium Battery Maintenance in Electric Vehicles

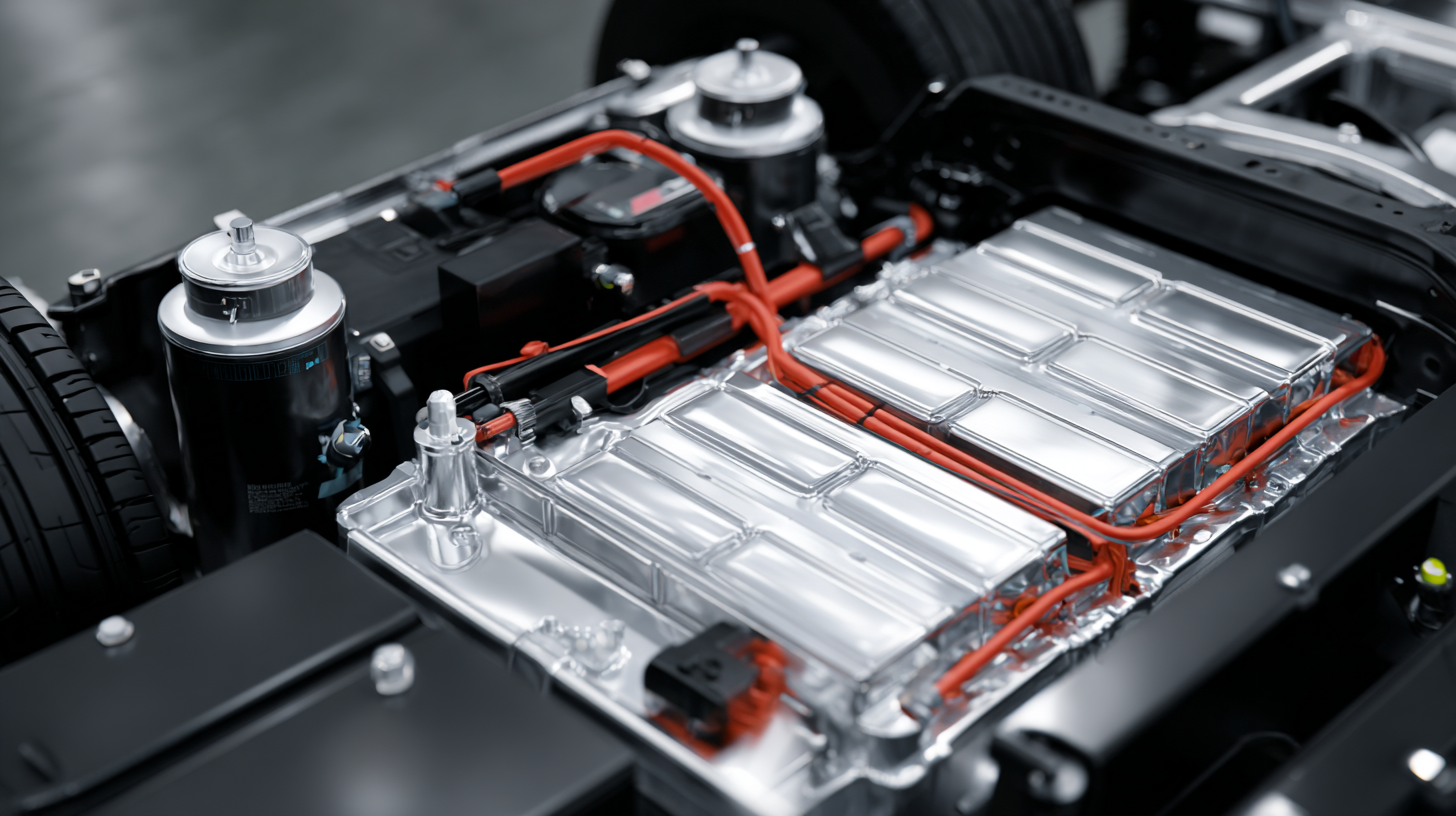

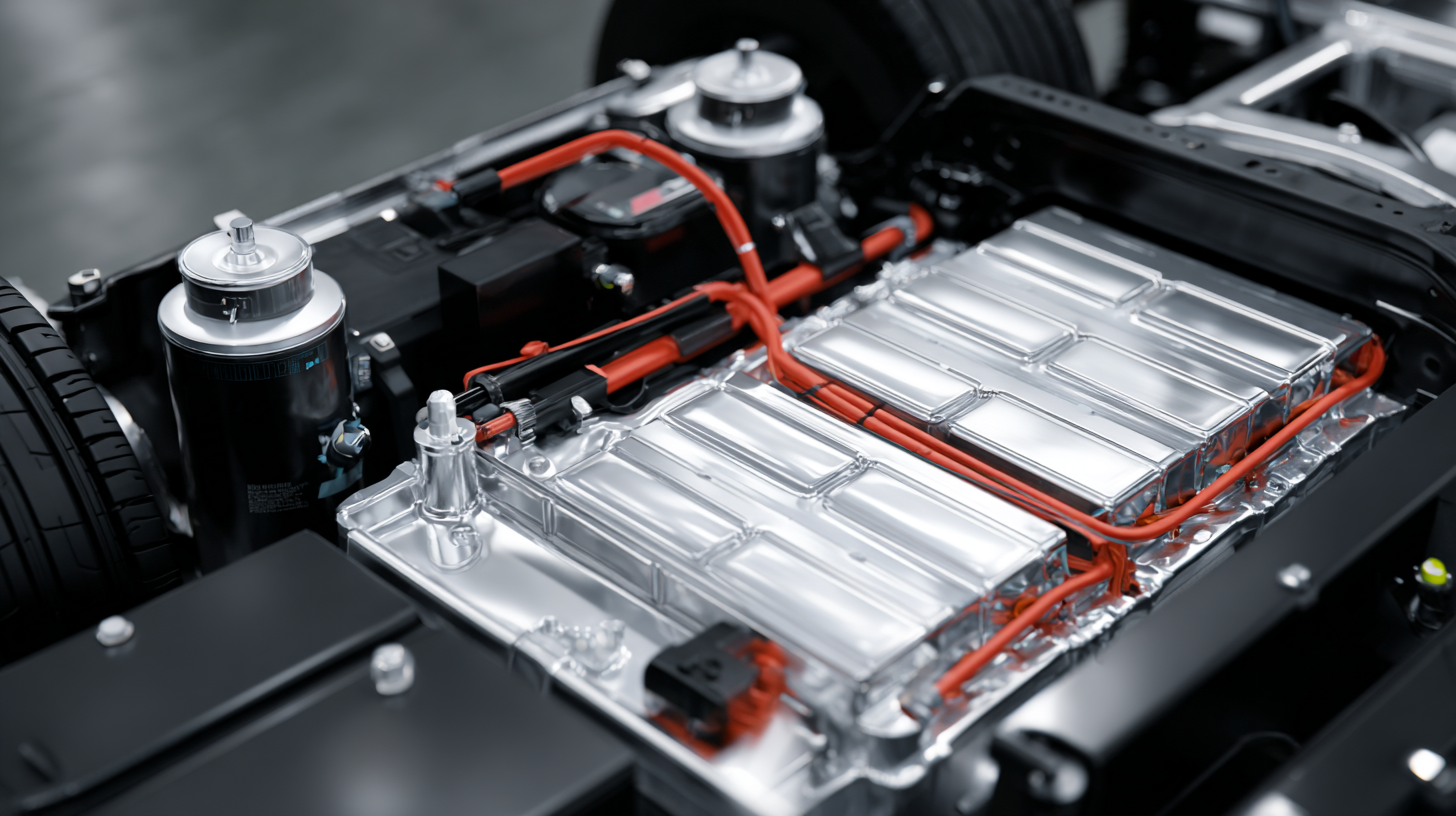

Lithium batteries are at the heart of electric vehicle technology, offering high energy density and prolonged range. However, proper maintenance is crucial to ensure their longevity and safety. One of the primary safety measures is to keep the battery temperature within optimal ranges. Overheating can lead to thermal runaway, potentially causing fires or damaging the battery's internal structure. Utilizing the built-in thermal management systems effectively and parking the vehicle in shaded areas can help mitigate these risks.

Regularly checking the battery's health is also essential. Monitoring for signs of swelling, leakage, or corrosion can indicate underlying issues. It's advisable to follow the manufacturer's guidance on charging practices, such as avoiding extreme states of charge. Additionally, using only recommended chargers can significantly reduce the risk of electrical anomalies. Implementing these best practices not only enhances safety but can also extend the life of the lithium batteries, ensuring that electric vehicle owners get the most out of their investment.

What You Need to Know About Lithium Auto Battery Technologies - Safety Measures and Best Practices for Lithium Battery Maintenance in Electric Vehicles

| Aspect |

Details |

| Battery Type |

Lithium-ion |

| Common Applications |

Electric Vehicles, Hybrid Vehicles |

| Typical Voltage |

3.6 - 3.7 V per cell |

| Charging Time |

30 minutes to 8 hours depending on charger type |

| Common Safety Issues |

Overheating, short circuit, electrode degradation |

| Best Maintenance Practices |

Regular monitoring, avoiding deep discharges, thermal management |

| Lifespan |

Approximately 8-15 years or 1500-3000 cycles |

| Environmental Considerations |

Recycling and responsible disposal methods are crucial |

Lithium auto batteries are rapidly becoming the preferred choice in the automotive industry, significantly outpacing traditional lead-acid and nickel-based options. One of the primary advantages of lithium batteries is their

Lithium auto batteries are rapidly becoming the preferred choice in the automotive industry, significantly outpacing traditional lead-acid and nickel-based options. One of the primary advantages of lithium batteries is their