Why Are Shipping Li Ion Batteries Important for Safety?

The shipping of lithium-ion batteries is a critical issue in today's world. With the rise of electric vehicles and portable electronics, these batteries are everywhere. Experts stress the importance of safety in this industry. Dr. Emily Carter, a leading authority on battery technology, once stated, "Ensuring safety in shipping lithium-ion batteries is essential to prevent catastrophic failures."

In recent years, incidents involving shipping lithium-ion batteries have raised alarm. The potential for fire or explosion makes safety protocols vital. Companies must adhere to strict guidelines to mitigate these risks. Improper packaging can lead to serious consequences. Each battery should be correctly labeled and handled with care.

While progress has been made in safety measures, gaps still exist. Not all shippers fully understand the inherent risks. This lack of awareness can result in dangerous situations. Educating the workforce about the hazards of shipping lithium-ion batteries is crucial. Continuous improvement and awareness are necessary to protect lives and property.

Importance of Li-Ion Batteries in Modern Shipping Practices

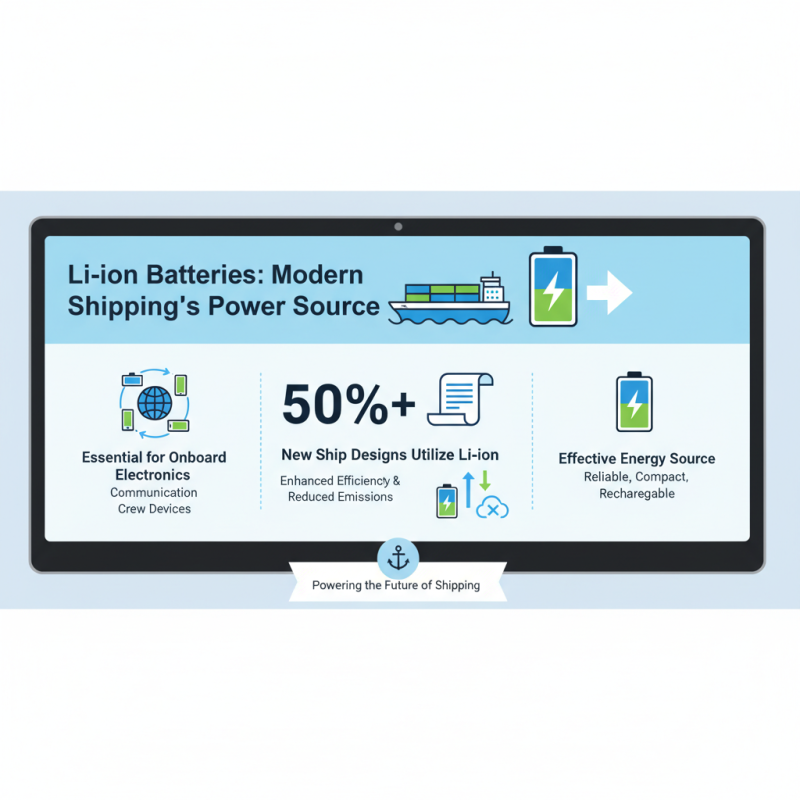

Lithium-ion (Li-ion) batteries have become essential in modern shipping practices. They provide an effective energy source for various electronic devices on board ships. According to a recent industry report, over 50% of new ship designs now utilize Li-ion batteries to enhance efficiency and reduce emissions.

While the benefits are clear, there are safety concerns. Li-ion batteries can pose fire risks if damaged or improperly handled. In fact, data shows that incidents related to battery fires have increased by 30% in recent years. Shipping companies must prioritize proper storage and handling of these batteries to ensure safety protocols are followed.

Tips: Always check battery condition before loading. Use protective casings during transport to prevent damage. Ensure that crew members are trained in emergency procedures related to battery fires. The industry must remain vigilant. Awareness and preparedness can save lives and resources.

The transition to Li-ion batteries is not without challenges. The technology is evolving rapidly, leading to inconsistencies in quality. Not all batteries meet safety standards. Reviewing battery specifications and certifications is crucial. By prioritizing safety, the shipping industry can maximize the advantages of Li-ion technology while minimizing risks.

Safety Hazards Associated with Shipping Li-Ion Batteries

Shipping lithium-ion (Li-ion) batteries poses significant safety hazards. These batteries can overheat, catch fire, or even explode if damaged or improperly packed. Many incidents have been reported during transportation, leading to serious consequences, including property damage and injury. Understanding these risks is crucial for anyone involved in shipping.

One major concern is thermal runaway. This occurs when a cell in the battery overheats, causing a chain reaction. It can happen from a short circuit or physical damage. Shipping practices sometimes overlook the fragility of these batteries. It’s easy to see why proper handling and packaging are essential. Mishandled packages might damage the battery, triggering a fire.

There’s also the risk associated with multiple batteries shipped together. A single compromised unit can jeopardize the entire shipment. The ideal method is to ship batteries individually or in protective cases. Inadequate labeling and documentation can lead to confusion. Misleading packaging might assume that all is well when, in reality, it is not. These factors demand awareness and diligence to prevent accidents and ensure safety.

Why Are Shipping Li-Ion Batteries Important for Safety? - Safety Hazards Associated with Shipping Li-Ion Batteries

| Hazard Type |

Description |

Safety Measures |

Regulatory Compliance |

| Fire Risk |

Li-ion batteries can catch fire if they are damaged or short-circuited. |

Use protective packaging and handle with care. |

Must comply with UN regulations for hazardous materials. |

| Explosive Risk |

Overheating can lead to thermal runaway and explosion. |

Monitor temperature during transport, especially in extreme conditions. |

Comply with IATA regulations for air transport. |

| Chemical Leakage |

Leakage of electrolyte can be harmful. |

Ensure batteries are sealed and intact before shipping. |

Adhere to local waste disposal regulations for damaged batteries. |

| Short Circuit |

Improper packaging can cause short circuits. |

Use appropriate insulation materials. |

Follow international guidelines for battery transportation. |

Regulatory Standards for Shipping Li-Ion Batteries

Shipping lithium-ion (Li-Ion) batteries requires strict adherence to regulatory standards. These batteries are widely used in electronics, but their potential hazards cannot be ignored. Regulatory bodies enforce guidelines to ensure safe transport. They help minimize risks associated with fires and chemical leaks.

Understanding these regulations is crucial for manufacturers and shippers. Some key standards include packaging, labeling, and documentation requirements. Proper packaging helps prevent damage during transit. All labels must clearly indicate potential hazards. Ignoring these regulations can lead to serious consequences. It’s important to stay informed about local and international rules.

Tips: Always double-check your packaging. Use appropriate materials to prevent short circuits. Keep an eye on the battery charge levels. A charged battery poses more risks during shipping. Never underestimate the importance of thorough documentation. Accurate paperwork can save time and ensure compliance with regulations.

Best Practices for Handling and Packaging Li-Ion Batteries

Handling and packaging lithium-ion batteries requires strict adherence to safety best practices. These batteries are sensitive to temperature, punctures, and short circuits. The International Air Transport Association (IATA) notes that nearly 50% of reported air transport incidents involve battery malfunctions. It’s vital to store batteries in a cool, dry place, away from direct sunlight.

When packaging, use materials that provide cushioning and prevent movement. Labels should clearly indicate the contents and include handling instructions. As per recent data from the Consumer Product Safety Commission, improper packaging can lead to fires and explosions, posing serious risks during transport. Batteries should not be stacked haphazardly; maintain a space between them to allow for airflow.

Training personnel in handling protocols is crucial. Regular drills help ensure everyone knows what to do in emergencies. A recent survey revealed that 30% of workers felt unprepared for battery-related incidents. This underscores the need for ongoing education and evaluation. Battery safety isn't just about compliance; it's about cultivating a culture of responsibility and awareness.

Technological Advancements in Li-Ion Battery Safety Measures

Lithium-ion batteries power our electronics and vehicles. Their safety is crucial. Recent technological advancements are improving safety measures significantly. These improvements focus on materials, design, and monitoring systems. High-temperature resistant materials can prevent overheating. Some designs now incorporate protective barriers against short circuits.

Monitoring systems play a vital role, too. They track the battery’s condition in real-time. This ensures early detection of potential issues. Some systems even shut down the battery when problems are detected. This proactive approach can prevent serious accidents.

Tips: Always check the battery health regularly. Use proper charging equipment to avoid damage. Store batteries in a cool, dry place. Be cautious with damaged batteries. Reflect on the use of these technologies. Safety is a shared responsibility in this rapidly evolving field. Keeping updated on safety practices is essential.