How to Optimize Lithium Ion Automotive Battery Performance for Maximum Efficiency

In the fast-evolving automotive industry, the quest for

maximum efficiency has brought

lithium ion automotive batteries to the forefront of

technological innovation. As the backbone of electric vehicles, these batteries not only enable

longer driving ranges but also play a crucial role in enhancing overall vehicle performance.

However, optimizing the performance of lithium ion automotive batteries is essential to fully

harness their potential.

This guide delves into key strategies and best practices for maximizing battery efficiency,

addressing factors such as charging cycles,

thermal management, and advanced battery management systems.

By implementing these optimization techniques, manufacturers and vehicle owners alike can ensure that

their lithium ion automotive batteries operate at peak performance,

extending their lifespan and improving the driving experience. Join us as we explore the critical elements

that contribute to the efficient functioning

of these essential power sources.

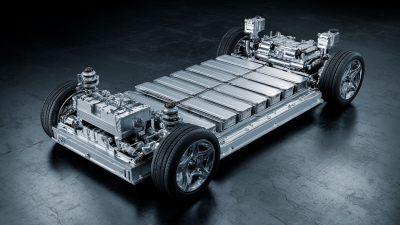

Understanding the Basics of Lithium Ion Automotive Batteries

Lithium-ion automotive batteries have become the cornerstone of modern electric vehicles (EVs) due to their high energy density and lightweight properties. These batteries operate on the principle of lithium ions moving between the anode and cathode, which allows for efficient energy storage and discharge. According to a report by the International Energy Agency (IEA), global sales of electric vehicles, heavily reliant on lithium-ion technology, reached around 6.6 million units in 2021, marking a 108% increase from the previous year. Understanding the basic components and functionalities of these batteries is crucial in optimizing their performance for maximum efficiency.

Lithium-ion automotive batteries have become the cornerstone of modern electric vehicles (EVs) due to their high energy density and lightweight properties. These batteries operate on the principle of lithium ions moving between the anode and cathode, which allows for efficient energy storage and discharge. According to a report by the International Energy Agency (IEA), global sales of electric vehicles, heavily reliant on lithium-ion technology, reached around 6.6 million units in 2021, marking a 108% increase from the previous year. Understanding the basic components and functionalities of these batteries is crucial in optimizing their performance for maximum efficiency.

Tip 1: Ensure proper thermal management of your battery system. EV batteries generally perform best within a temperature range of 20°C to 25°C. Maintaining optimal conditions can enhance overall performance and lifespan.

Tip 2: Regularly monitor the battery's state of charge (SoC) and state of health (SoH). Research by the U.S. Department of Energy indicates that a well-maintained SoC can lead to a 20-30% increase in battery life, ultimately maximizing your vehicle's efficiency.

By grasping these foundational elements and implementing efficient management techniques, EV manufacturers and owners can significantly enhance battery performance, leading to longer ranges and improved sustainability.

Key Factors Influencing Battery Performance and Efficiency

Optimizing the performance of lithium-ion automotive batteries is crucial for maximizing efficiency in electric vehicles. Several key factors influence battery performance, starting with temperature management. Lithium-ion batteries operate optimally within a specific temperature range. Operating at extreme temperatures can lead to reduced capacity and increased wear. Implementing thermal management systems, such as cooling channels or heating elements, ensures that the battery maintains an ideal temperature, improving its lifespan and overall efficiency.

Another significant factor is the battery management system (BMS). An advanced BMS monitors individual cell voltages, temperatures, and state of charge, facilitating balanced charging and discharging. This technology prevents overcharging, which can damage cells, and undercharging, which can lead to reduced performance. Additionally, the use of high-quality materials in battery construction, such as superior electrode materials and electrolytes, can enhance energy density and reduce internal resistance, leading to more efficient power usage during operation.

Techniques for Enhancing Charge and Discharge Cycles

Optimizing the charge and discharge cycles of lithium-ion automotive batteries is critical for enhancing efficiency and longevity. According to a report by the International Energy Agency (IEA), proper management of these cycles can improve a battery's overall lifespan by up to 30%. This is achieved by maintaining optimal temperature ranges during both charging and discharging processes, which should ideally be between 20°C to 25°C. Higher temperatures can accelerate degradation, while lower temperatures can cause inefficiencies in charge acceptance.

Tip 1: Regularly monitor and calibrate battery management systems (BMS) to ensure they optimize charge and discharge rates. Implementing advanced algorithms can help mitigate risks associated with overcharging and deep discharging, which are detrimental to battery health.

Tip 2: Employ regenerative braking systems in electric vehicles. Studies show that vehicles using regenerative braking can recover over 70% of kinetic energy during deceleration, thus extending the battery's discharge cycles significantly. This not only maximizes battery usage but also enhances the driving range between charges.

Improving battery performance also includes choosing the right charger. A fast-charging system can significantly reduce charging time but may harm long-term battery health if not matched with the battery's capabilities. Thus, it is essential to select chargers that conform to the specific lithium-ion battery requirements, promoting both safety and efficiency in the charging process.

Impact of Temperature Management on Battery Longevity

Temperature management is pivotal in optimizing lithium-ion automotive batteries, impacting their longevity and overall performance. As the industry embraces the rising demand for electric vehicles (EVs), effective thermal regulation becomes crucial. Research indicates that battery performance can degrade significantly when operating temperatures exceed the optimal range. Studies show that for lithium-ion batteries, a temperature increase of just 10°C can halve their lifespan, emphasizing the importance of maintaining an ideal thermal environment.

In the context of energy management, proper temperature control directly correlates with the vehicle's range and efficiency. State-of-the-art battery thermal management systems, such as immersion cooling, are emerging solutions that provide superior temperature regulation compared to traditional methods. Reports estimate that the energy storage market in China alone surpassed 200 billion yuan in 2022, primarily driven by advancements in battery technology and energy management practices. Such innovations not only enhance the safety and durability of batteries but also contribute to optimized energy consumption, improving the overall user experience in electric vehicles.

How to Optimize Lithium Ion Automotive Battery Performance for Maximum Efficiency - Impact of Temperature Management on Battery Longevity

| Temperature Range (°C) |

Cycle Life (Cycles) |

Capacity Retention (%) |

Optimal Charging Rate (C) |

Typical Applications |

| -20 to 0 |

300 |

80 |

0.5 |

Electric Scooters |

| 0 to 25 |

1000 |

90 |

1.0 |

Passenger Cars |

| 25 to 45 |

500 |

75 |

1.5 |

High-Performance Vehicles |

| Above 45 |

250 |

60 |

2.0 |

Heavy-Duty Trucks |

Innovative Technologies for Future Battery Optimization

As the automotive industry shifts towards electrification, innovative technologies are crucial for optimizing lithium-ion battery performance. One promising advancement is the development of solid-state batteries, which replace the traditional liquid electrolyte with a solid electrolyte. This shift not only enhances energy density but also significantly reduces the risk of thermal runaway, improving the overall safety and efficiency of electric vehicles. Manufacturers are also exploring new anode materials, such as silicon and lithium metal, which can inherently provide higher capacity and faster charging times compared to conventional graphite anodes.

Another exciting area of progression is the implementation of artificial intelligence and machine learning to refine battery management systems. By analyzing data from battery usage patterns and environmental factors, AI can predict degradation and optimize charging cycles, thus extending battery lifespan and maintaining peak performance. Additionally, advanced thermal management systems, which employ phase change materials and innovative heat dissipation techniques, can help maintain optimal operating temperatures, further enhancing efficiency and reliability. As these technologies evolve, the potential for future battery optimization in the automotive sector seems limitless, paving the way for longer-lasting and more efficient electric vehicles.

Lithium-ion automotive batteries have become the cornerstone of modern electric vehicles (EVs) due to their high energy density and lightweight properties. These batteries operate on the principle of lithium ions moving between the anode and cathode, which allows for efficient energy storage and discharge. According to a report by the International Energy Agency (IEA), global sales of electric vehicles, heavily reliant on lithium-ion technology, reached around

Lithium-ion automotive batteries have become the cornerstone of modern electric vehicles (EVs) due to their high energy density and lightweight properties. These batteries operate on the principle of lithium ions moving between the anode and cathode, which allows for efficient energy storage and discharge. According to a report by the International Energy Agency (IEA), global sales of electric vehicles, heavily reliant on lithium-ion technology, reached around