How to Safely Handle and Transport UN3480 Lithium Ion Batteries for Your Business

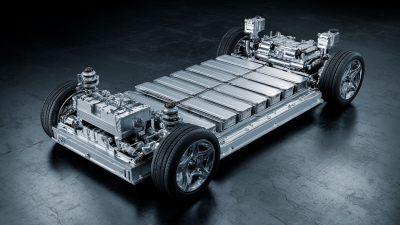

In today's technology-driven world, the demand for portable electronic devices and electric vehicles has significantly increased the use of UN3480 lithium ion batteries. According to the International Battery Association, the global lithium-ion battery market is projected to reach $100 billion by 2027, influencing various industries from consumer electronics to renewable energy solutions. However, with this growth comes the responsibility of ensuring the safe handling and transportation of these batteries, especially given the specific regulations surrounding UN3480 lithium ion batteries, which are classified as dangerous goods. The increasing incidents of battery-related fires and incidents during transportation have prompted regulatory bodies to enforce stringent guidelines to mitigate risks.

This blog will provide essential insights and best practices for businesses to safely handle and transport un3480 lithium ion batteries, ensuring compliance and the safety of personnel and the environment.

Best Practices for Safely Handling UN3480 Lithium Ion Batteries in the Workplace

Handling and transporting UN3480 lithium-ion batteries safely is critical for businesses engaged in shipping electronic devices or energy storage systems. These batteries, while efficient and widely used, pose unique risks if not managed properly. Implementing best practices in the workplace can significantly reduce the chances of accidents and ensure regulatory compliance.

One essential tip for safely handling these batteries is to always inspect them for any signs of damage or leakage before moving them. Damaged batteries can be hazardous and must be dealt with according to specific guidelines. Additionally, ensure that team members wear proper personal protective equipment (PPE) to prevent exposure to potential hazards. Regular training sessions should be conducted to keep employees informed about the latest safety protocols.

One essential tip for safely handling these batteries is to always inspect them for any signs of damage or leakage before moving them. Damaged batteries can be hazardous and must be dealt with according to specific guidelines. Additionally, ensure that team members wear proper personal protective equipment (PPE) to prevent exposure to potential hazards. Regular training sessions should be conducted to keep employees informed about the latest safety protocols.

When it comes to transportation, make sure to utilize appropriate packaging that meets international shipping standards. This includes using strong outer containers and cushioning materials to protect the batteries during transit. It’s also advisable to label packages clearly to indicate that they contain lithium-ion batteries, which helps in handling them with care. Following these best practices not only promotes workplace safety but also aligns with certifications in lithium battery handling, enhancing your business's overall reputation in the industry.

Understanding the Regulatory Framework for Transporting Lithium Ion Batteries (IATA, DOT Guidelines)

Transporting UN3480 lithium-ion batteries requires a thorough understanding of various regulatory frameworks to ensure safety and compliance. The International Air Transport Association (IATA) provides specific guidelines that address the classification, packaging, and labeling of these batteries. Compliance with IATA regulations is crucial for businesses involved in international shipping, as these guidelines specifically help minimize the risks associated with air transport. Batteries must be packed in a way that protects them from short-circuiting, damage, and environmental exposure, and they should be placed in strong outer packaging to prevent leakage or contamination.

In addition to IATA regulations, the U.S. Department of Transportation (DOT) has established its own set of guidelines for transporting hazardous materials, including lithium-ion batteries. These regulations emphasize proper documentation, container specification, and labeling to alert handlers to potential risks. For example, all shipments must include a declaration of Dangerous Goods and adhere to specific limits on the watt-hour ratings for lithium-ion batteries. By closely following both IATA and DOT guidelines, businesses can navigate the complexities of transporting these materials safely while minimizing legal liabilities associated with non-compliance. Understanding these frameworks not only ensures safety but also fosters trust with customers and partners in the supply chain.

Key Safety Equipment and Precautions for Handling Lithium Ion Batteries

When handling and transporting UN3480 lithium-ion batteries, prioritizing safety is crucial. Key safety equipment includes personal protective gear, such as gloves and goggles, to shield against potential hazards. Additionally, utilizing insulated containers can prevent accidental short circuits, which are a common risk associated with lithium batteries. It is also important to inspect batteries for any signs of damage or swelling before moving them, as these can indicate a higher likelihood of thermal runaway, a phenomenon that poses severe safety risks.

Precautions should extend to the charging environment as well. Ensuring proper ventilation while charging and storing batteries reduces the risk of heat buildup, which can lead to fires. Recent incidents, such as the tragic fatal e-bike fire, highlight the vital importance of adhering to safety guidelines. Communities are increasingly implementing educational campaigns on safe usage and disposal practices for lithium-ion batteries. By integrating these safety measures into everyday practices, businesses can significantly mitigate the risks associated with lithium-ion battery handling and transport.

How to Safely Handle and Transport UN3480 Lithium Ion Batteries for Your Business - Key Safety Equipment and Precautions for Handling Lithium Ion Batteries

| Aspect |

Details |

| Battery Type |

Lithium Ion (UN3480) |

| Weight Limit per Package |

Not exceeding 300 kg |

| Packaging Requirements |

Strong outer packaging with cushioning materials |

| Safety Equipment |

Fire extinguisher, eye protection, gloves |

| Handling Precautions |

Avoid short circuits, control temperature |

| Transport Requirements |

Labeling, secure in the vehicle |

| Emergency Measures |

Evacuate area, call emergency services |

| Training Requirements |

Staff training on battery handling and emergency response |

Real-Life Incident Statistics: Risks and Consequences of Improper Transport

When it comes to the transport of UN3480 lithium-ion batteries, the stakes are high. Real-life incident statistics reveal that improper handling can lead to catastrophic consequences. According to recent reports, there have been numerous instances of fires and explosions during transport, largely attributed to inadequate packaging and failure to comply with regulatory guidelines. These incidents not only pose significant safety risks for workers and transportation personnel but also raise serious environmental concerns when batteries leak hazardous materials.

The consequences of mishandling lithium-ion batteries extend beyond physical harm. Businesses face potential legal ramifications, including fines and penalties, should they fail to adhere to safety regulations. The financial impact of an incident can be devastating, affecting insurance premiums and leading to costly disruptions in operations. Moreover, a company’s reputation can be on the line, as customers become wary of engaging with businesses that show negligence in such critical safety practices. As the statistics demonstrate, prioritizing safe transport methods is not just a best practice; it is essential for ensuring the well-being of individuals and the integrity of the organization.

Training Your Staff: Essential Knowledge for Safe Lithium Battery Management

When it comes to safely handling and transporting UN3480 lithium-ion batteries, equipping your staff with essential knowledge is crucial. Training your employees on the specific risks associated with lithium batteries can significantly reduce incidents during handling and transport. Ensure that your team understands the importance of recognizing hazardous signs, such as swelling or overheating, which may signal a compromised battery.

**Tips:** Conduct regular training sessions that include hands-on demonstrations of how to properly inspect, store, and manage these batteries. Encourage staff to report any damaged or suspicious batteries immediately to prevent potential hazards from escalating.

Another important aspect is educating your workforce on compliance with regulations surrounding lithium battery transport. Familiarize them with packaging requirements and labeling that must be adhered to when shipping these batteries.

**Tips:** Create a comprehensive manual that outlines best practices and regulatory guidelines, and make it easily accessible. Additionally, consider running mock drills to reinforce training and improve your team's preparedness for potential emergencies related to lithium-ion batteries.

Safety Training Hours for Lithium Ion Battery Management

This chart illustrates the monthly training hours required for key topics related to the safe handling and transportation of UN3480 lithium-ion batteries. Emphasizing these areas ensures that staff are well-informed and capable of managing lithium batteries safely.

One essential tip for safely handling these batteries is to always inspect them for any signs of damage or leakage before moving them. Damaged batteries can be hazardous and must be dealt with according to specific guidelines. Additionally, ensure that team members wear proper personal protective equipment (PPE) to prevent exposure to potential hazards. Regular training sessions should be conducted to keep employees informed about the latest safety protocols.

One essential tip for safely handling these batteries is to always inspect them for any signs of damage or leakage before moving them. Damaged batteries can be hazardous and must be dealt with according to specific guidelines. Additionally, ensure that team members wear proper personal protective equipment (PPE) to prevent exposure to potential hazards. Regular training sessions should be conducted to keep employees informed about the latest safety protocols.