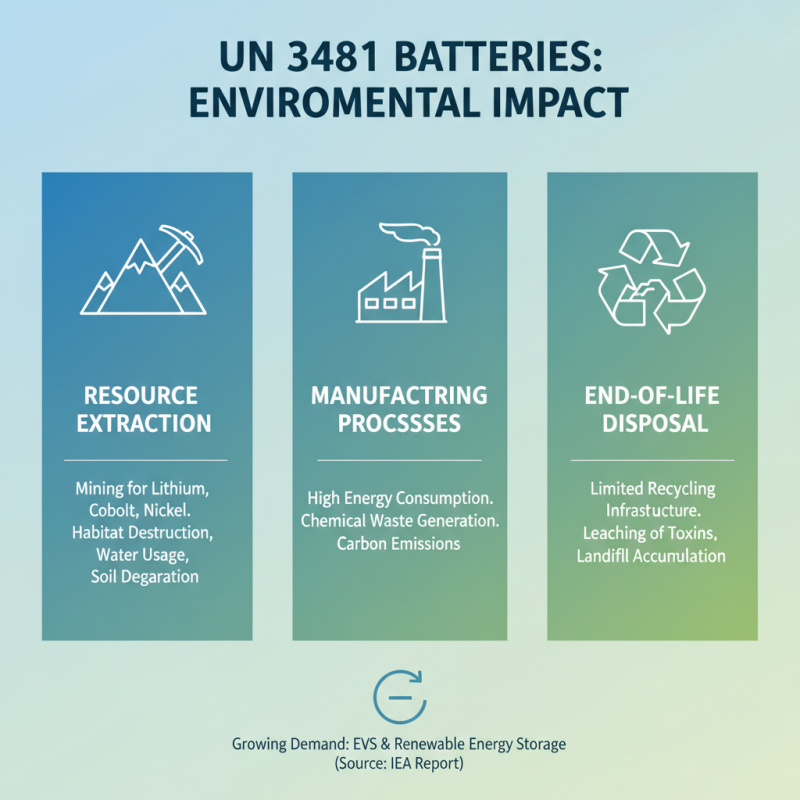

The environmental impact of using UN 3481 batteries, commonly referred to as lithium-ion batteries transported in equipment, is significant and warrants careful consideration. According to a report by the International Energy Agency (IEA), the growth of the electric vehicle market and renewable energy storage is driving an increase in demand for lithium-ion battery production. This trend can lead to a more significant environmental footprint if not managed correctly, particularly in terms of resource extraction, manufacturing processes, and end-of-life disposal.

The production of lithium-ion batteries often involves the extraction of raw materials such as lithium, cobalt, and nickel, which can have detrimental effects on local ecosystems and communities. A study published in Nature Sustainability highlighted that mining these minerals can result in habitat destruction, water pollution, and adverse social consequences. Additionally, the energy-intensive manufacturing processes contribute to greenhouse gas emissions, with estimates suggesting that battery production can emit up to 150 kg of CO2 equivalent per kWh produced.

However, there are also efforts being made to mitigate these environmental impacts through advancements in battery recycling technologies and the development of more sustainable sourcing practices. A circular economy approach, which emphasizes recycling and reusing battery components, could significantly reduce the ecological footprint associated with battery usage. According to a report from the Ellen MacArthur Foundation, if lithium-ion batteries were effectively recycled, over 95% of the raw materials could be recovered, thus lessening the demand for virgin materials and their associated environmental costs.