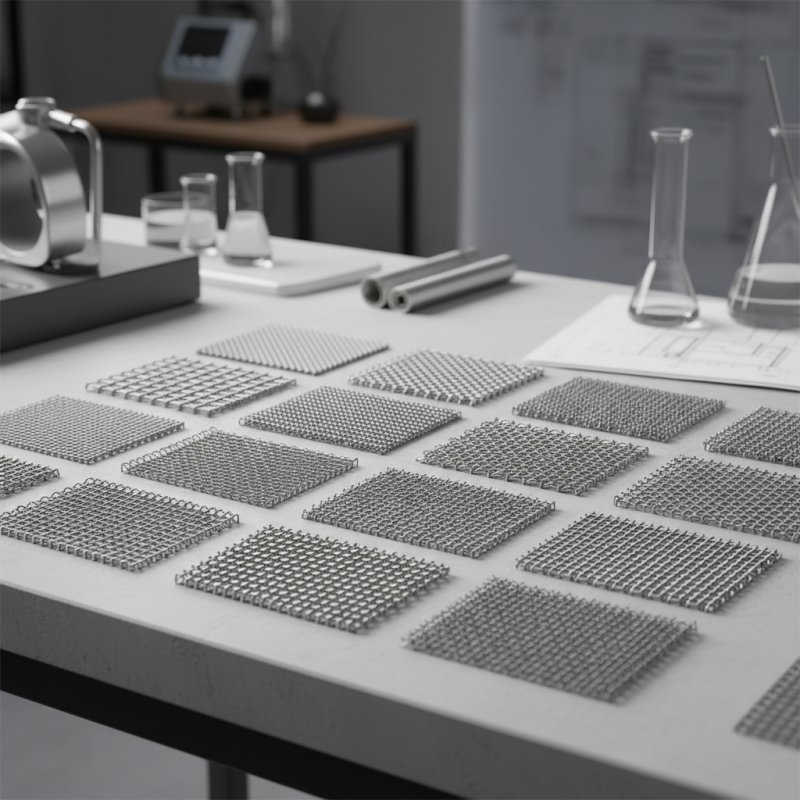

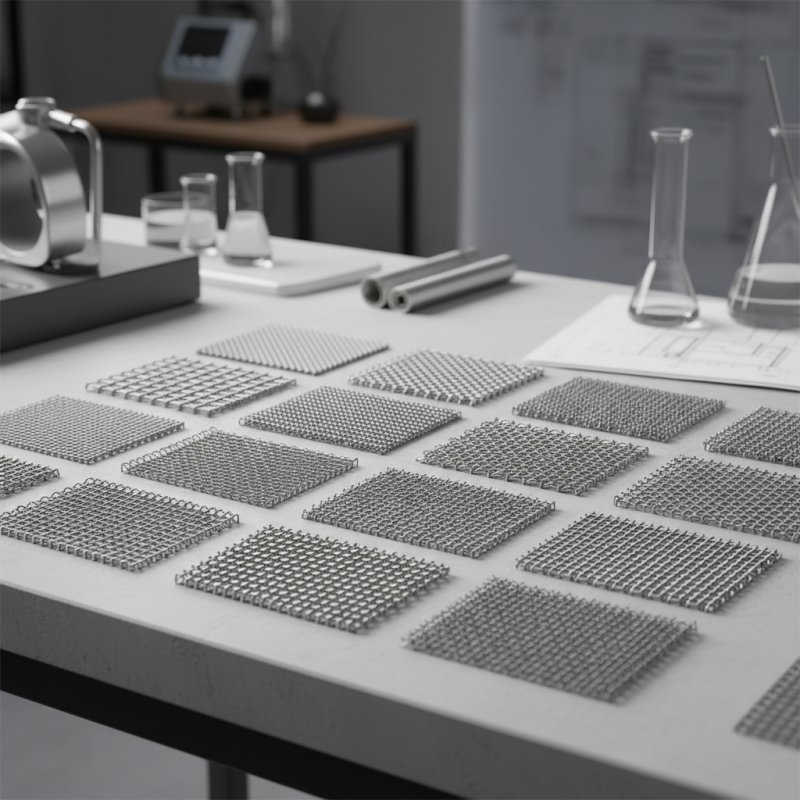

Top 10 Uses of Stainless Steel Wire Mesh for Your Projects?

stainless steel wire mesh is an essential material across various industries. Its versatility makes it ideal for numerous applications, from architectural designs to filtration systems. According to the Stainless Steel Wire Fabrication Market Report, the demand for stainless steel mesh is projected to grow by 5% annually.

Industry experts like Dr. Emily Carter emphasize its significance. She states, "The adaptability of stainless steel wire mesh is unmatched, providing solutions that meet diverse project needs." This material not only offers strength and durability but also corrosion resistance, making it valuable in harsh environments.

However, it’s vital to recognize the limitations of stainless steel wire mesh. For instance, selecting the wrong gauge or weave can lead to unexpected failures in projects. Understanding specifications and project requirements becomes critical. The right choice ensures functionality without compromising on quality or performance.

Applications of Stainless Steel Wire Mesh in Construction Projects

Stainless steel wire mesh is a versatile material widely used in construction projects. Its durability and corrosion resistance make it ideal for various applications. For instance, it is often used for concrete reinforcement. The mesh adds strength to the concrete and prevents cracks. It is crucial in areas that experience heavy loads. Builders find that it improves the longevity of structures.

Another application is in safety barriers. Stainless steel wire mesh provides protection on construction sites. It can keep debris away from workers, reducing accidents. Additionally, it is used for fencing. This type of mesh can secure perimeters, ensuring that unauthorized access is limited. The visibility of stainless steel adds a modern touch to the aesthetic.

Yet, some issues arise with stainless steel wire mesh. Installation can be tricky, requiring skilled labor. If not installed properly, it may lead to structural weaknesses. Cost is another factor; while durable, it can be more expensive than other materials. Therefore, careful consideration is needed before choosing stainless steel wire mesh for specific applications. Reflections on these challenges can lead to better planning for projects.

Benefits of Using Stainless Steel Wire Mesh in Industrial Settings

Stainless steel wire mesh is highly valued in industrial settings. It offers corrosion resistance and durability. This makes it an ideal choice for various applications. Industries use it for filtration, safety barriers, and more. The mesh provides strong support while remaining lightweight. In many places, it outperforms other materials. It withstands harsh environments like chemical plants and food processing.

Using stainless steel wire mesh enhances safety in workplaces. It can be used in machine guards and enclosures. This prevents accidents and protects workers. The transparency of the mesh allows for visibility while ensuring high security. Additionally, stainless steel wire mesh is easy to clean. In food industries, hygiene is paramount. Air and liquid can pass through, but contaminants cannot.

However, not all applications are perfect. Sometimes, the mesh can be expensive. This may limit its use in smaller projects. Moreover, installation may require skilled labor. It's essential to assess your needs carefully. Choosing the right type of mesh is crucial for optimal performance. Overall, stainless steel wire mesh is a practical choice, but one must consider its limitations.

How Stainless Steel Wire Mesh Enhances Filtration Systems

Stainless steel wire mesh plays a critical role in filtration systems. Its durability and resistance to corrosion make it ideal for water and air purification. Data shows that up to 90% of industrial filtration applications utilize some form of metal mesh. This highlights its importance in maintaining efficiency and extending the lifespan of filtration equipment.

The mesh's openings can be precisely engineered to capture specific contaminants. For instance, a 0.5-millimeter mesh can filter particles as small as 100 microns. In contrast, finer meshes are essential in applications where even smaller particles must be trapped. Proper selection of mesh size can significantly impact overall filtration performance. Yet, the process can be tricky, as an inappropriate mesh might lead to reduced flow rates or inadequate filtration.

Many industries have seen improvements in product quality due to stainless steel wire mesh. Food and beverage producers benefit from enhanced purity standards. However, challenges like clogging remain a concern. Regular maintenance and checks are crucial to ensuring consistent filtration outcomes. Balancing efficiency with operational costs often requires thoughtful consideration. Each project should assess its unique needs before making mesh choices.

Creative Uses of Stainless Steel Wire Mesh in Art and Design

Stainless steel wire mesh offers a unique avenue for artistic expression in various forms of design. Artists have creatively repurposed this material to craft sculptures and installations. The mesh can mimic organic shapes or create geometric patterns that capture the eye. When light filters through, it creates stunning shadows. This interplay of light and material can evoke different emotions. Yet, achieving the perfect balance in such projects can often be challenging.

In interior design, stainless steel wire mesh serves as an intriguing element. Designers use it in partitions, allowing for privacy without losing openness. The sleek texture can enhance a modern aesthetic. However, integrating it into a space might not always go as planned. The reflective nature can sometimes overwhelm a simpler decor. Art and functionality must coexist, but finding harmony is often a process of trial and error. Embracing imperfections in this journey can lead to unexpected beauty in the final piece.

Maintenance Tips for Stainless Steel Wire Mesh in Various Applications

Stainless steel wire mesh is a versatile material used in many applications. However, proper maintenance is crucial to ensure its longevity. Regular cleaning helps prevent dirt and corrosion. Use mild detergents and a soft cloth. For stubborn stains, a gentle scrub may be needed.

In environments prone to harsh conditions, periodic inspections are vital. Check for signs of wear and tear. If any damage is found, consider replacement. Keeping the mesh dry can also prevent rust. It is essential, especially in humid areas.

Consider the installation environment. Outdoor installations may need extra protection. A protective coating or barrier can enhance durability. Remember, neglecting maintenance can lead to costly repairs and replacements. Taking these steps ensures your stainless steel wire mesh remains functional for a long time.

Top 10 Uses of Stainless Steel Wire Mesh