Top Trends in Industrial Lithium Batteries to Watch for in 2025

The landscape of industrial lithium batteries is poised for significant transformation as we approach 2025. With the growing emphasis on renewable energy sources and the electrification of various sectors, understanding the emerging trends in this domain has never been more crucial. Industry expert Dr. Susan Hamilton, a renowned authority on energy storage solutions, asserts, “The future of industrial lithium batteries will be defined not only by their efficiency but also by innovations aimed at sustainability and scalability.”

As we delve into the evolving dynamics of this industry, key trends such as advanced manufacturing techniques, enhanced battery lifespan, and integration with renewable energy systems are expected to take center stage. The race for improved energy density and reduced environmental impact will drive research and development, setting the benchmark for future advancements. Moreover, new applications across various industries will further solidify the significance of industrial lithium batteries, highlighting their role in supporting a greener and more resilient economy.

As we explore these trends, it becomes imperative to recognize how they will shape the future of energy storage, influencing everything from electric vehicles to large-scale renewable installations. Understanding these developments will not only enable stakeholders to make informed decisions but also ensure the successful integration of industrial lithium batteries into the global energy landscape.

Key Innovations Driving Industrial Lithium Battery Technology in 2025

As we look ahead to 2025, several key innovations are poised to transform industrial lithium battery technology, ultimately enhancing performance and sustainability. One of the most significant trends is the advancement in solid-state battery technology. According to a recent report by the International Energy Agency, solid-state batteries can potentially offer energy densities exceeding 400 Wh/kg, marking a substantial improvement over current lithium-ion technologies. This advancement not only promises longer-lasting power solutions for industrial applications but also addresses safety concerns related to traditional liquid electrolytes.

Another notable trend is the incorporation of advanced recycling processes. The global industrial lithium battery market is projected to grow significantly, reaching an estimated value of $184 billion by 2025, as stated by a report from MarketsandMarkets. With this growth comes the pressing need for sustainable practices, leading to innovations in battery recycling. New methodologies that allow for the efficient recovery of valuable materials such as lithium, cobalt, and nickel are being developed, reducing the environmental impact of battery production and facilitating a circular economy in battery supply chains. Efforts in recycling technology not only mitigate resource depletion but also contribute to lower lifecycle costs for industrial users, making lithium batteries more economically and environmentally viable.

The Impact of Sustainability Practices on Lithium Battery Production

The lithium battery industry is undergoing a significant transformation influenced heavily by sustainability practices. As the demand for electric vehicles and renewable energy storage continues to rise, the environmental impact of lithium battery production has come under increased scrutiny. According to a report by the International Energy Agency (IEA), global lithium demand is expected to increase nearly tenfold by 2030, creating a pressing need for more sustainable extraction and production methods.

In response, many companies are investing in innovative recycling technologies and sourcing methods to reduce their carbon footprint. The battery recycling market is projected to reach USD 18.5 billion by 2030, growing at a compound annual growth rate (CAGR) of 22% from 2023. Improvements in recycling efficiency can reclaim up to 95% of lithium and other valuable materials, significantly reducing the need for virgin materials, which often involve environmentally harmful mining practices. Furthermore, green chemistry processes are being adopted to ensure that the production of lithium batteries not only minimizes waste but also uses less energy compared to traditional methods.

The shift towards sustainability is not merely a regulatory necessity but is increasingly becoming a competitive advantage. A recent survey indicated that 70% of consumers are willing to pay a premium for products made using sustainable practices. This trend is likely to influence manufacturers' strategies as they aim to attract environmentally conscious customers while addressing the challenges posed by climate change and resource depletion. By prioritizing sustainability, the lithium battery industry is poised to meet the demands of tomorrow while protecting the planet.

Emerging Applications of Industrial Lithium Batteries Across Various Sectors

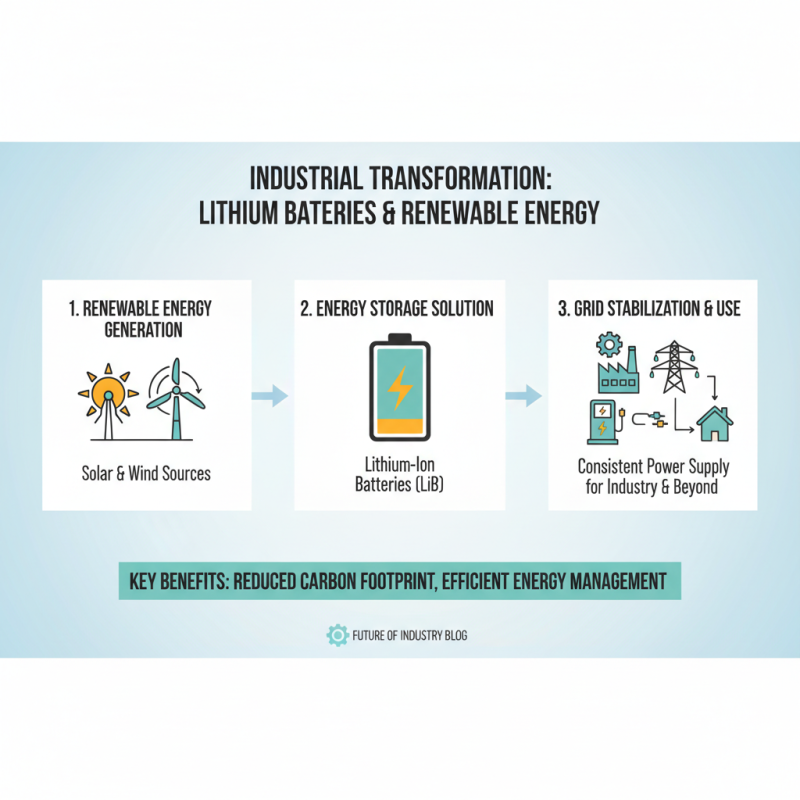

The industrial sector is set to witness significant transformation in the coming years, especially with the increasing adoption of lithium batteries across various applications. One of the most notable emerging applications is in the realm of renewable energy storage. As industries strive to reduce their carbon footprints, lithium batteries offer efficient solutions for storing energy generated from solar and wind sources. These batteries enable smoother energy management and help maintain a consistent power supply, which is increasingly vital as investment in renewable infrastructure grows.

Another area where industrial lithium batteries are making strides is in electric vehicles (EVs) and transportation logistics. The push for sustainable alternatives to fossil fuels is propelling the rapid development of electric fleets, utilizing lithium technology to enhance performance and extend range. Additionally, advancements in battery recycling methods are paving the way for a circular economy, where used batteries can be reclaimed and repurposed for future energy needs, thus minimizing waste and environmental impact.

Lastly, the integration of lithium batteries in smart manufacturing and automation is set to reshape operational efficiency. As industries implement the Internet of Things (IoT) and advanced robotics, reliable power sources are crucial for maintaining continuous operations. Lithium batteries are proving to be the backbone of these technologies, providing the necessary energy to drive intelligent systems and enabling real-time data processing. This synergy will not only streamline processes but also facilitate innovation across manufacturing sectors, embodying the future of industrial energy solutions.

Market Trends and Consumer Demands Influencing Lithium Battery Advancements

As we look ahead to 2025, the landscape of industrial lithium batteries is set to evolve significantly, driven by a confluence of market trends and consumer demands. One of the most notable trends is the increasing emphasis on sustainability, as industries strive to reduce their carbon footprints. According to a report by the International Energy Agency, the demand for lithium batteries is expected to triple by 2030, primarily due to the rising adoption of renewable energy sources and electric vehicles. This surge in demand will push manufacturers to adopt greener production processes and materials, ensuring that the entire lifecycle of lithium batteries aligns with global sustainability goals.

In addition to environmental considerations, consumer demand for longer-lasting and more efficient batteries continues to shape advancements in the lithium battery sector. Research conducted by the Battery Innovation Center indicates that consumers prioritize energy density and charging speed, pushing manufacturers to innovate with new materials and battery chemistries. Furthermore, the growing integration of smart technologies in battery management systems is enhancing performance monitoring and safety features, appealing to both industrial users and end consumers. As these trends converge, the industrial lithium battery market is poised for transformative growth, driven by the dual imperatives of sustainability and enhanced consumer expectations.

Top Trends in Industrial Lithium Batteries to Watch for in 2025

| Trend |

Description |

Market Impact |

Consumer Demand |

| Solid-State Batteries |

Increased energy density and safety compared to traditional lithium-ion batteries. |

Expected to dominate the market by providing longer-lasting power solutions. |

Growing consumer demand for electric vehicles with extended range. |

| Recycling Innovations |

Advancements in battery recycling processes to reclaim lithium and other materials. |

Reduction in raw material costs and environmental impact. |

Increased demand for sustainable products by eco-conscious consumers. |

| Enhanced Battery Management Systems |

Smart systems that monitor and optimize battery performance and longevity. |

Improved safety and efficiency leading to better user experience. |

Consumers seeking reliability and performance from energy storage solutions. |

| Fast Charging Technologies |

Development of systems that allow rapid charging of batteries without overheating. |

Potential to accelerate adoption of electric vehicles and portable devices. |

Increasing consumer preferences for convenience and quick access to power. |

| Improved Energy Density |

Higher capacity batteries that can store more energy in a smaller footprint. |

Market competitiveness boosted by longer-lasting battery solutions. |

Demand for compact and lightweight devices is driving innovation. |

Challenges and Opportunities in the Lithium Battery Supply Chain for 2025

As we look ahead to 2025, the lithium battery supply chain faces a dual-edged sword of challenges and opportunities. One major challenge is the increasing demand for lithium-ion batteries driven by the electric vehicle (EV) market, which is projected to grow at a compound annual growth rate (CAGR) of over 20% according to recent industry reports. However, this surging demand creates pressure on the supply chain for key raw materials, including lithium, cobalt, and nickel. Constraints in mining processes, geopolitical tensions, and fluctuations in raw material prices can significantly impact production timelines and costs, causing ripple effects throughout the industry.

Moreover, recycling and sustainability present both a challenge and an opportunity for the lithium battery supply chain. The International Energy Agency (IEA) anticipates that by 2030, over 12 million metric tons of lithium-ion batteries will reach their end-of-life, necessitating efficient recycling strategies to recover valuable materials and reduce environmental impact. The development of innovative recycling technologies can offer significant advantages, potentially allowing companies to reclaim up to 95% of critical materials. As the industry adapts to these challenges, pioneers in lithium battery technology will likely invest in sustainable practices, thus strengthening their positions in the rapidly evolving market landscape.

Top Trends in Industrial Lithium Batteries to Watch for in 2025

This chart illustrates the expected growth in key metrics related to industrial lithium batteries by 2025. The data highlights trends in production capacity, electric vehicle adoption, and energy storage systems.